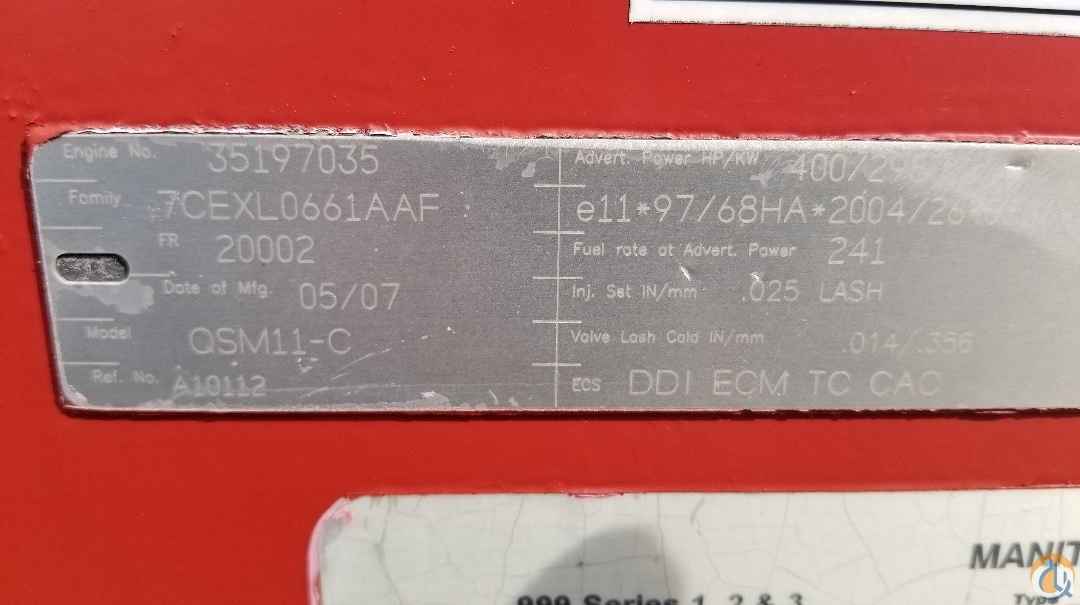

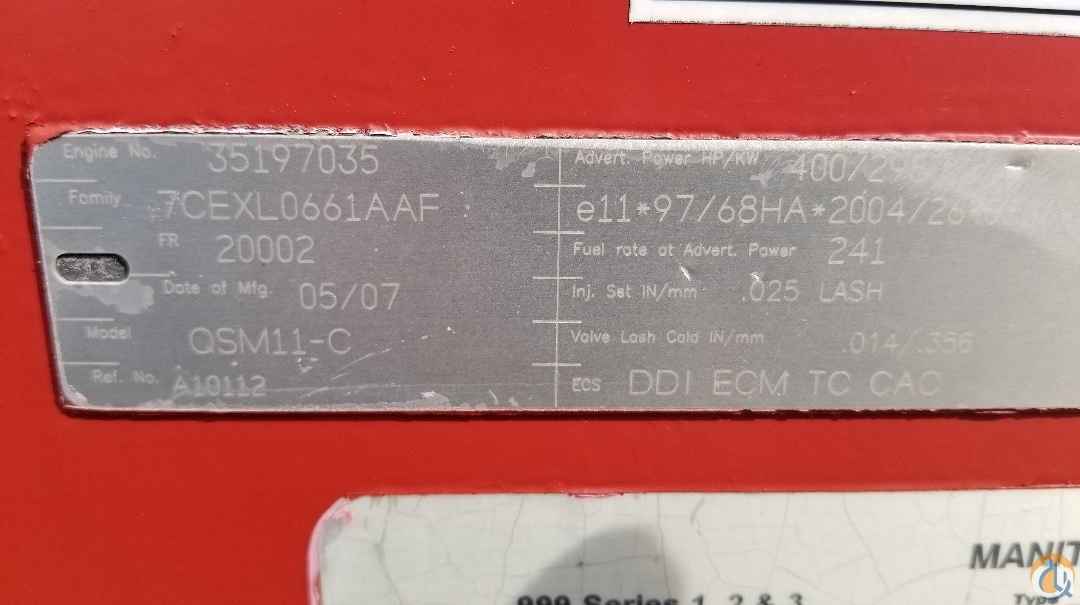

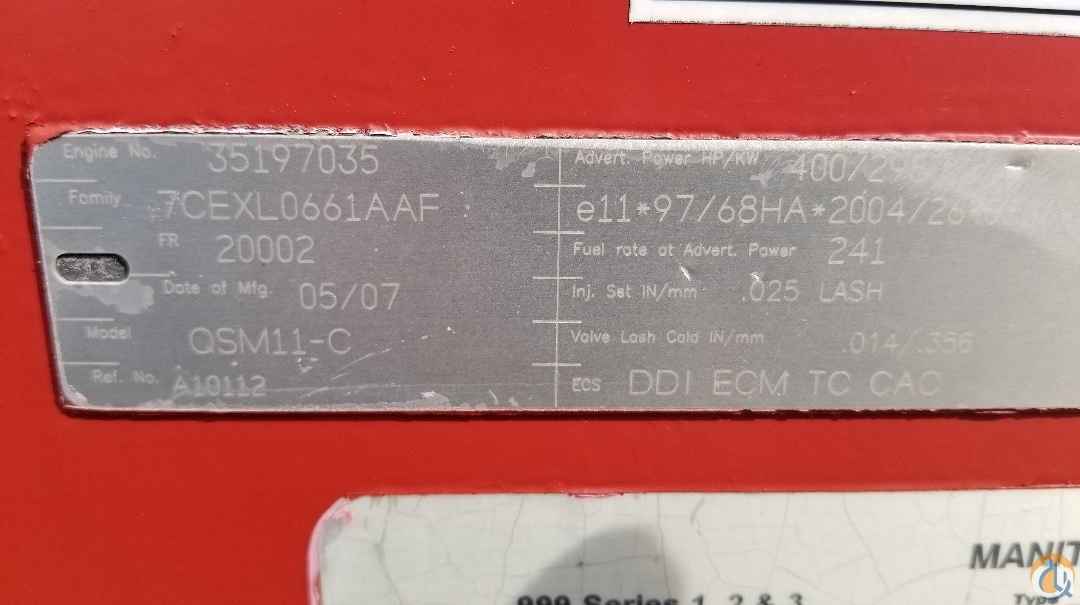

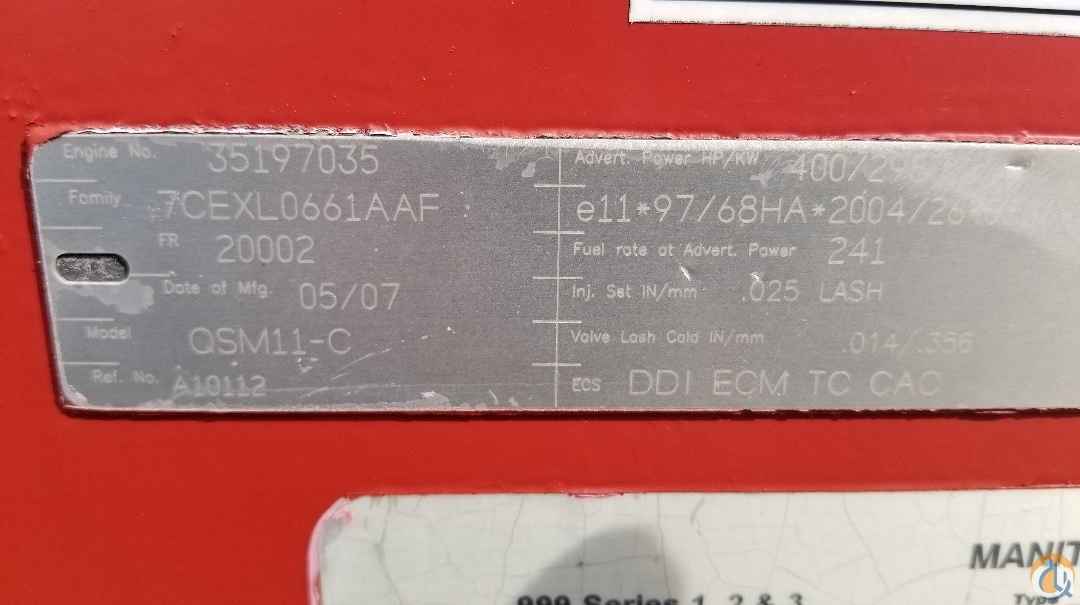

Year: 2007

Capacity: 275

Condition: Excellent

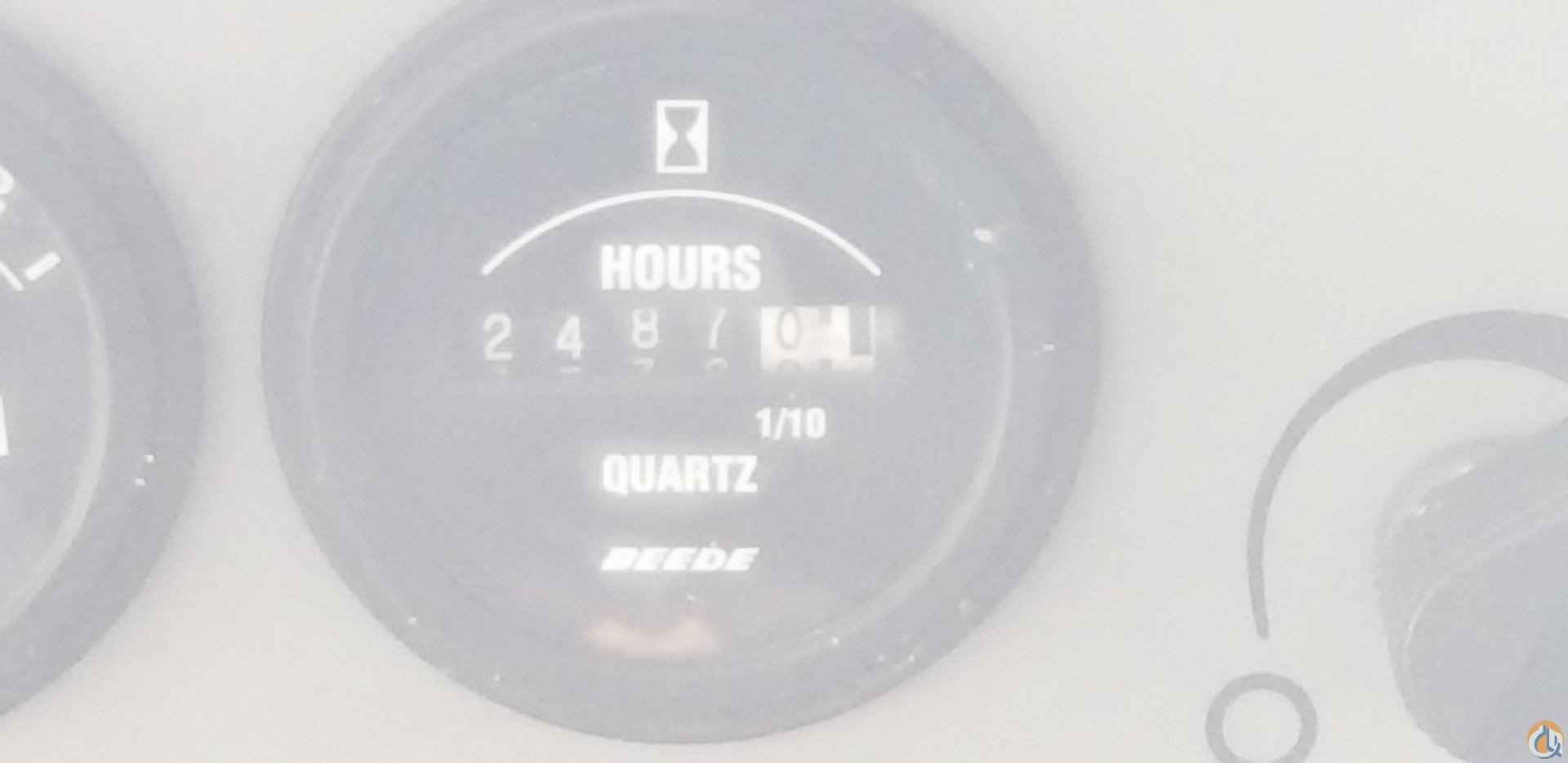

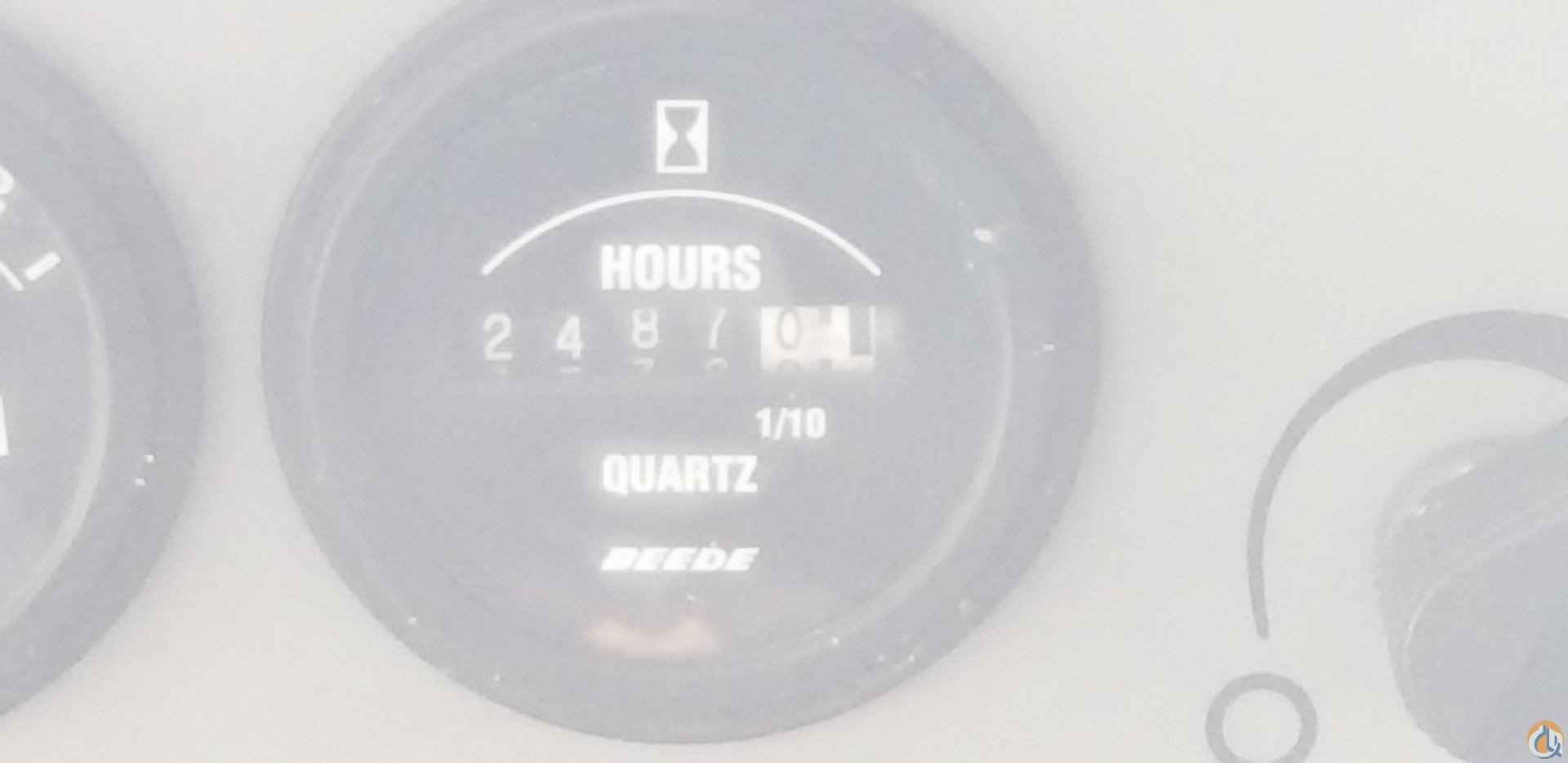

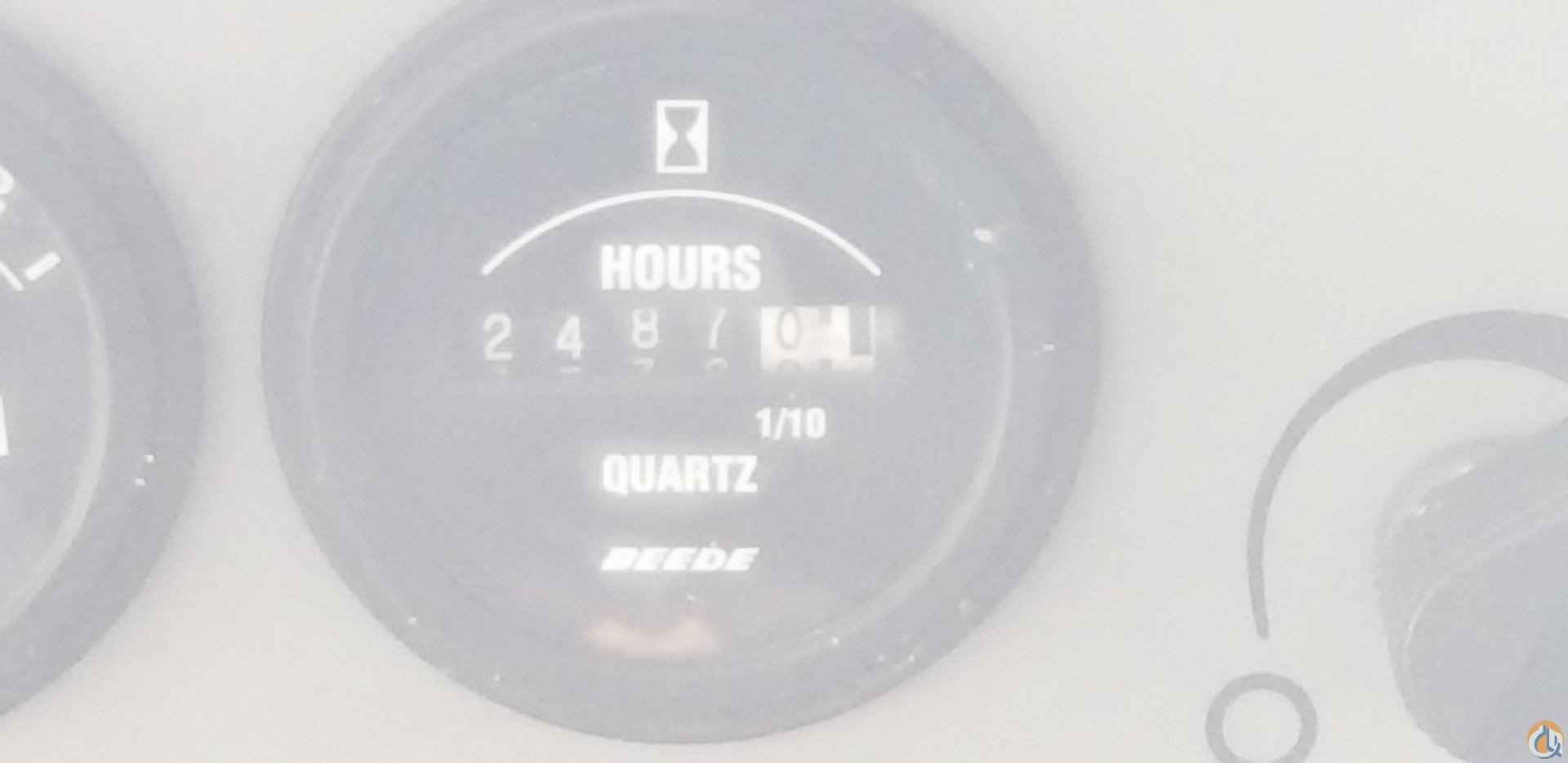

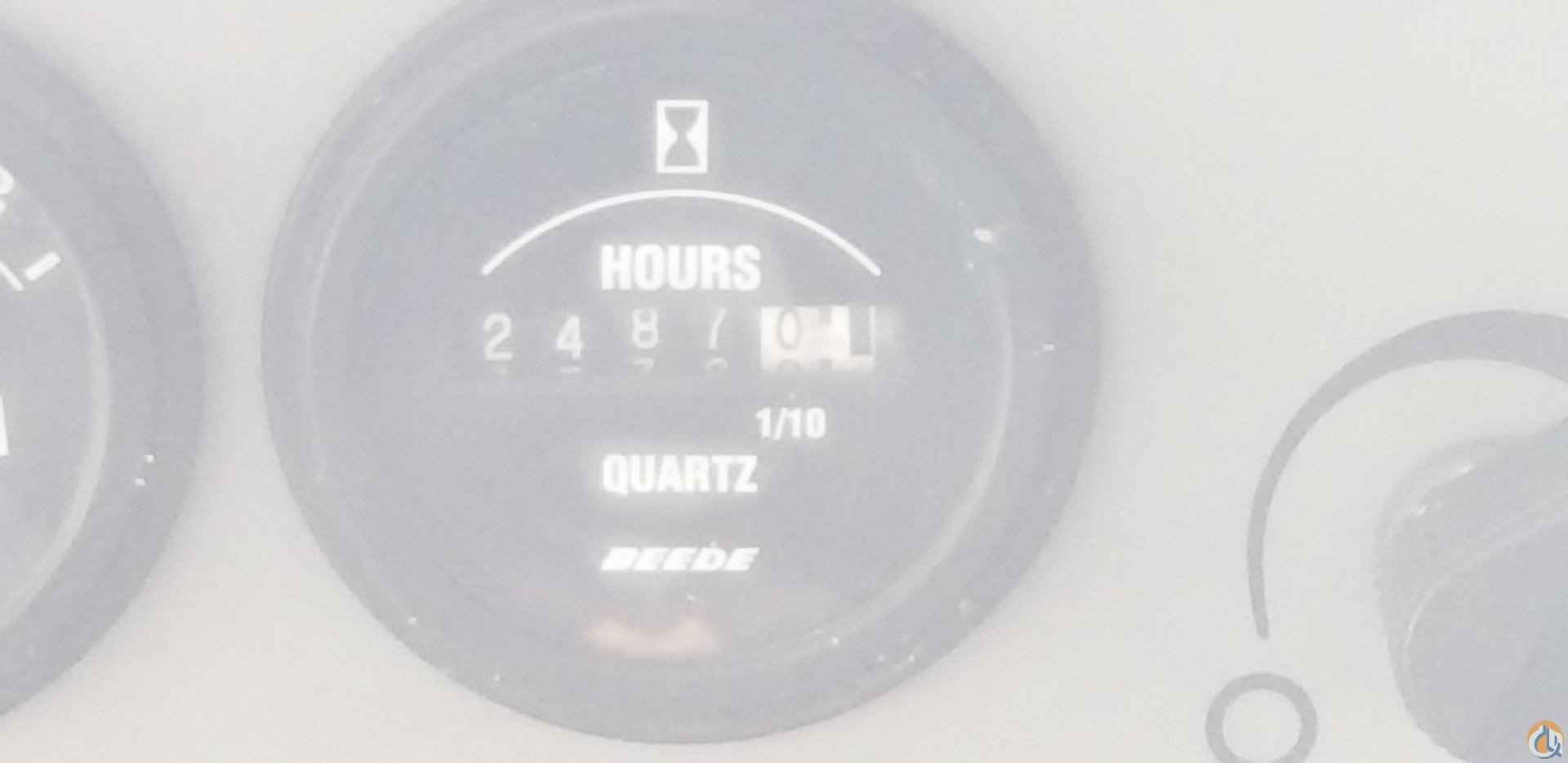

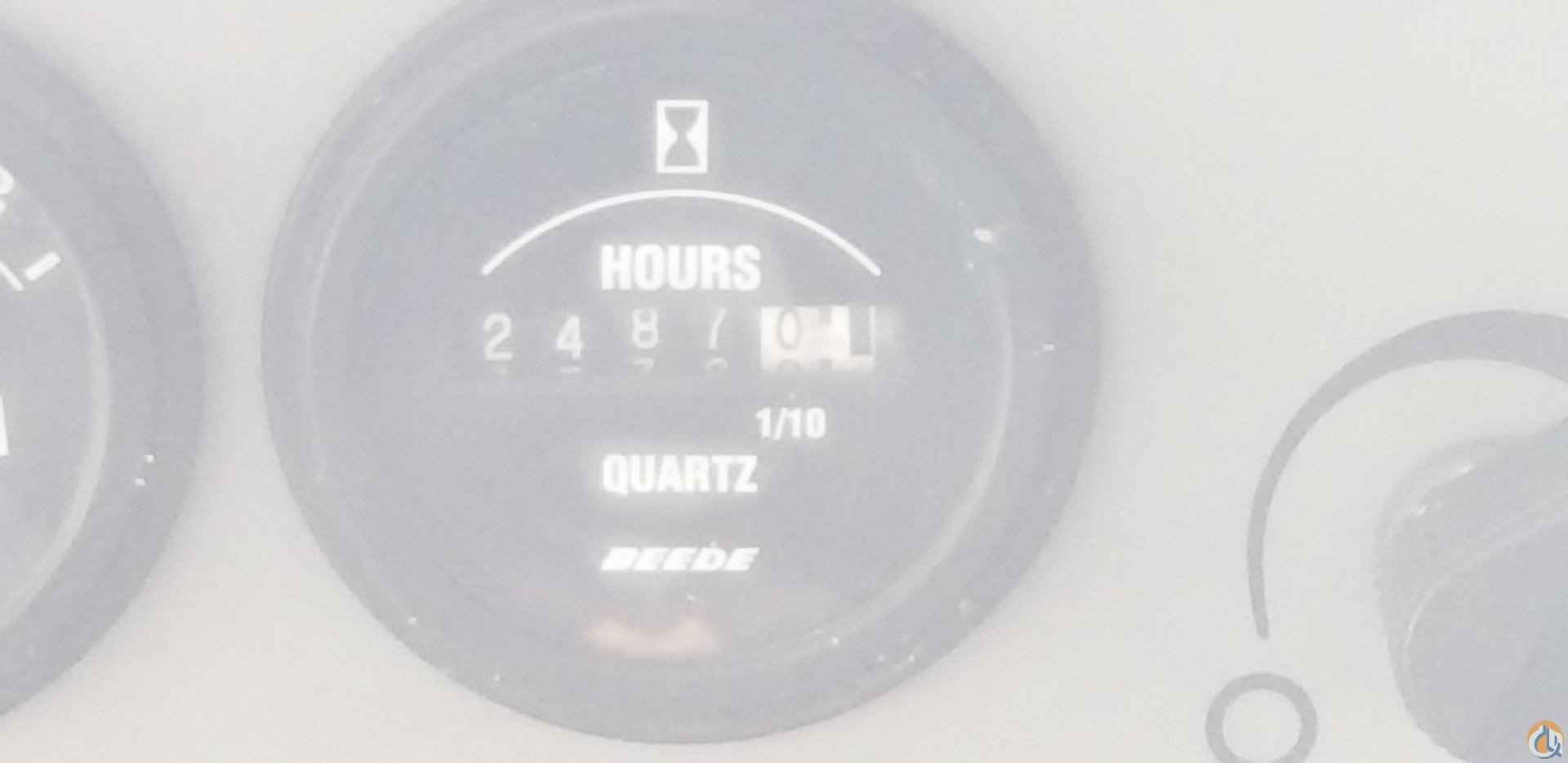

Hours: 12487

Serial #: 9991203

Location: New Orleans, Louisiana

Boom: 210

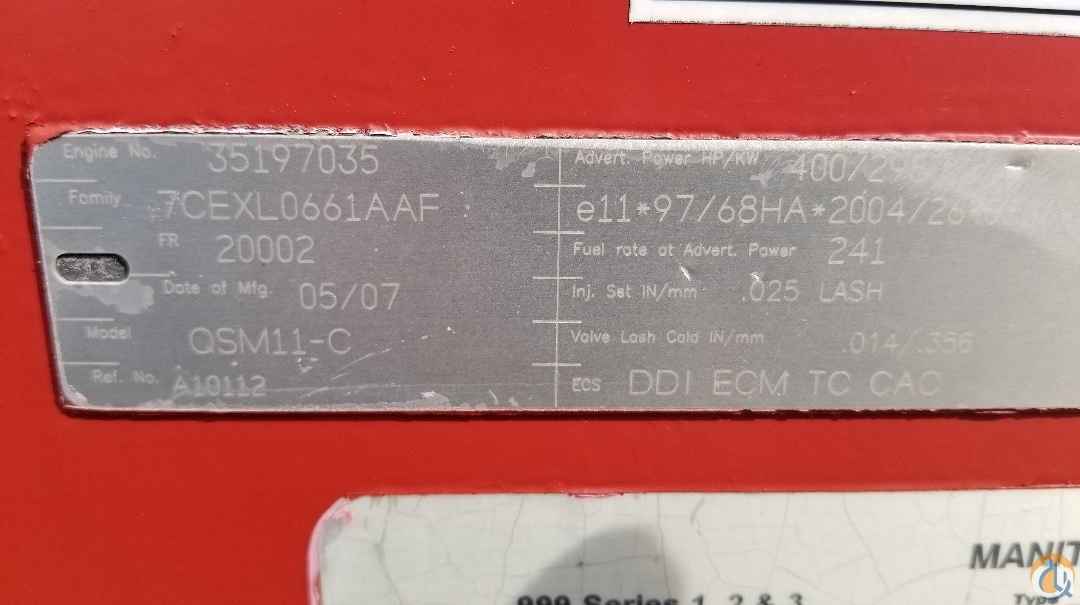

2007 Manitowoc 999 series 3- 275 ton Self Erecting Crane

Details: Cummins QSM11C, 400 hp, A/C, PLL, anti two-block, Mintowoc LMI, ... ind swing & travel, 299960 lb cwt, cwt removal device, 4 sheave 100 ton block & 200 ton block, 15 ton ball, 210 ft #82 HL angle boom, 60 ft #134 jib(Damaged), PLL, anti two-block, FACT connectors, windspeed indicator, Auxiliary Hoist Boom Tip,

Complete Refurb performed 5-2017 including all work listed below and a complete $100K paint Job

CRANE DISASSEMBLY/ LOAD OUT (Agrico New Orleans, LA)-1) Remove 210 ft. of main boom, and separate into individual sections.

2) Remove all counterweights and counterweight tray and store as required.

3) Jack crane up, via self-erect system, and remove both crawler side frames.

4) Mast forward and prepare upperworks for load-out and transit to HEES Belle Chasse, LA.

5) Load-out upperworks with carbody, boom butt, one 20 ft. boom insert, onto HEES

supplied trucks.

6) Transport via heavy haul all loaded components to HEES Belle Chasse, LA for repair.

- UPPERWORKS (Belle Chasse, LA)-

1) Stage crane in wash area, fully steam clean upper and lower works to remove all external contaminants.

2) Drain hydraulic fluids and stage machine in shop area.

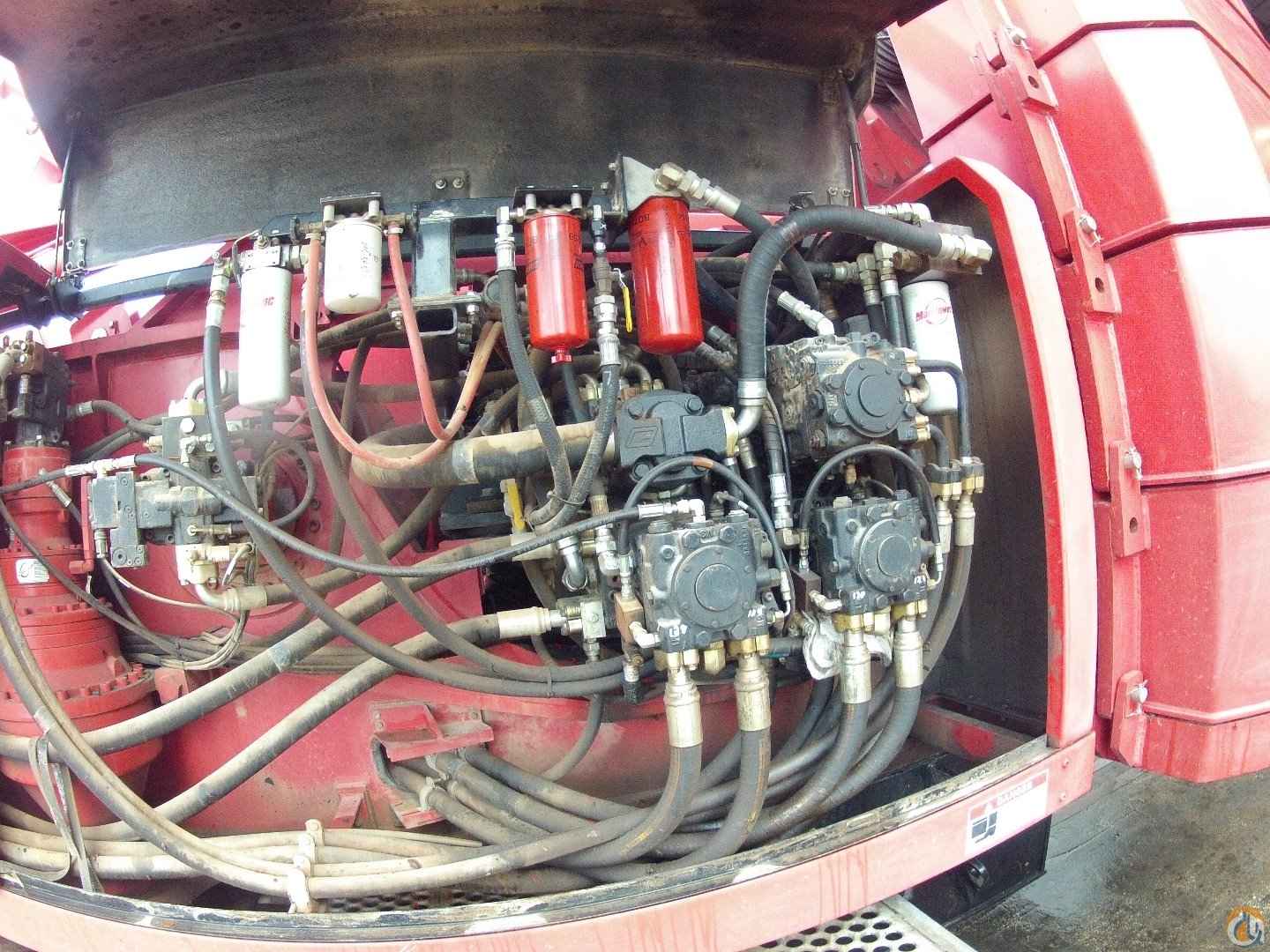

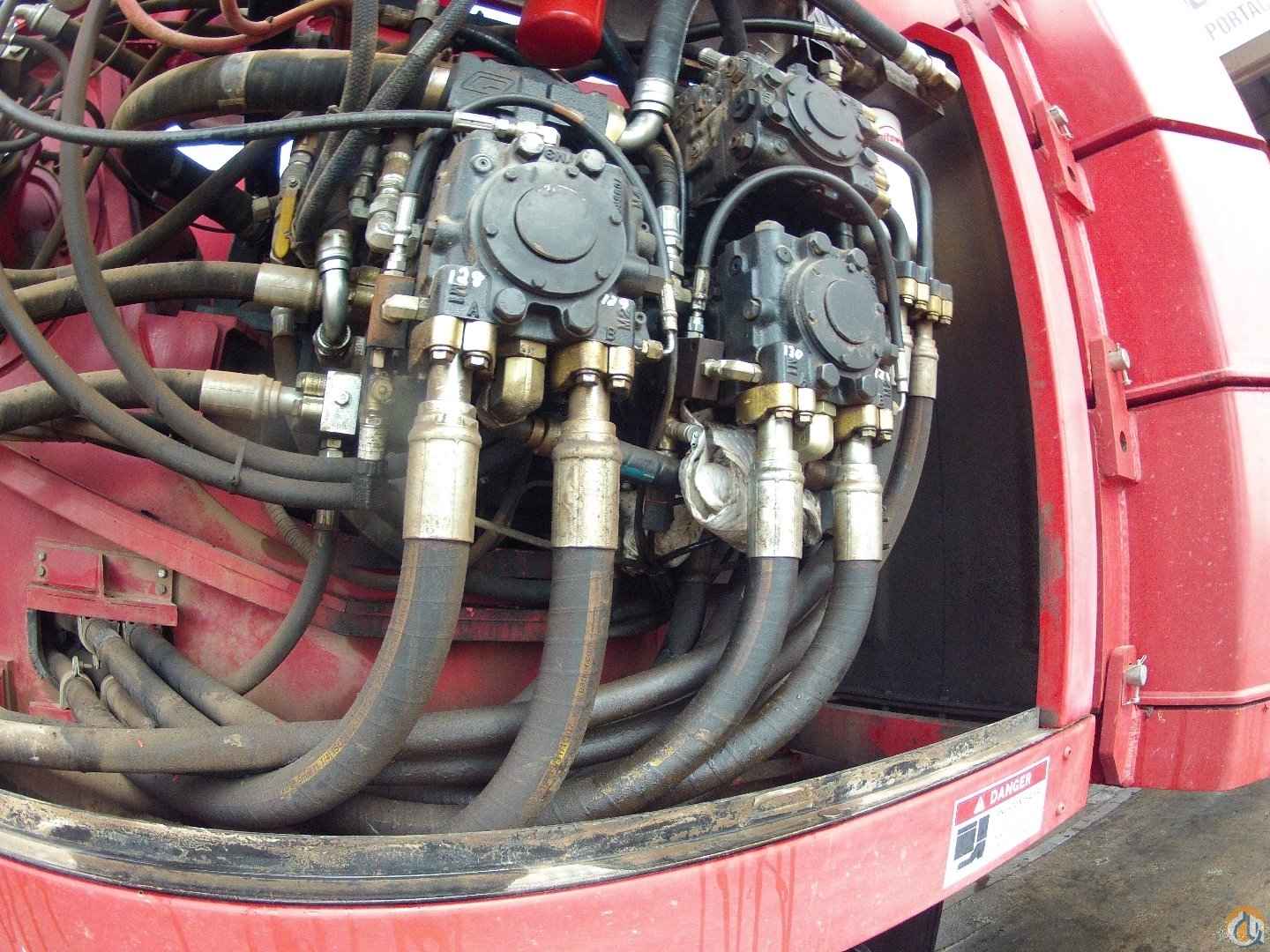

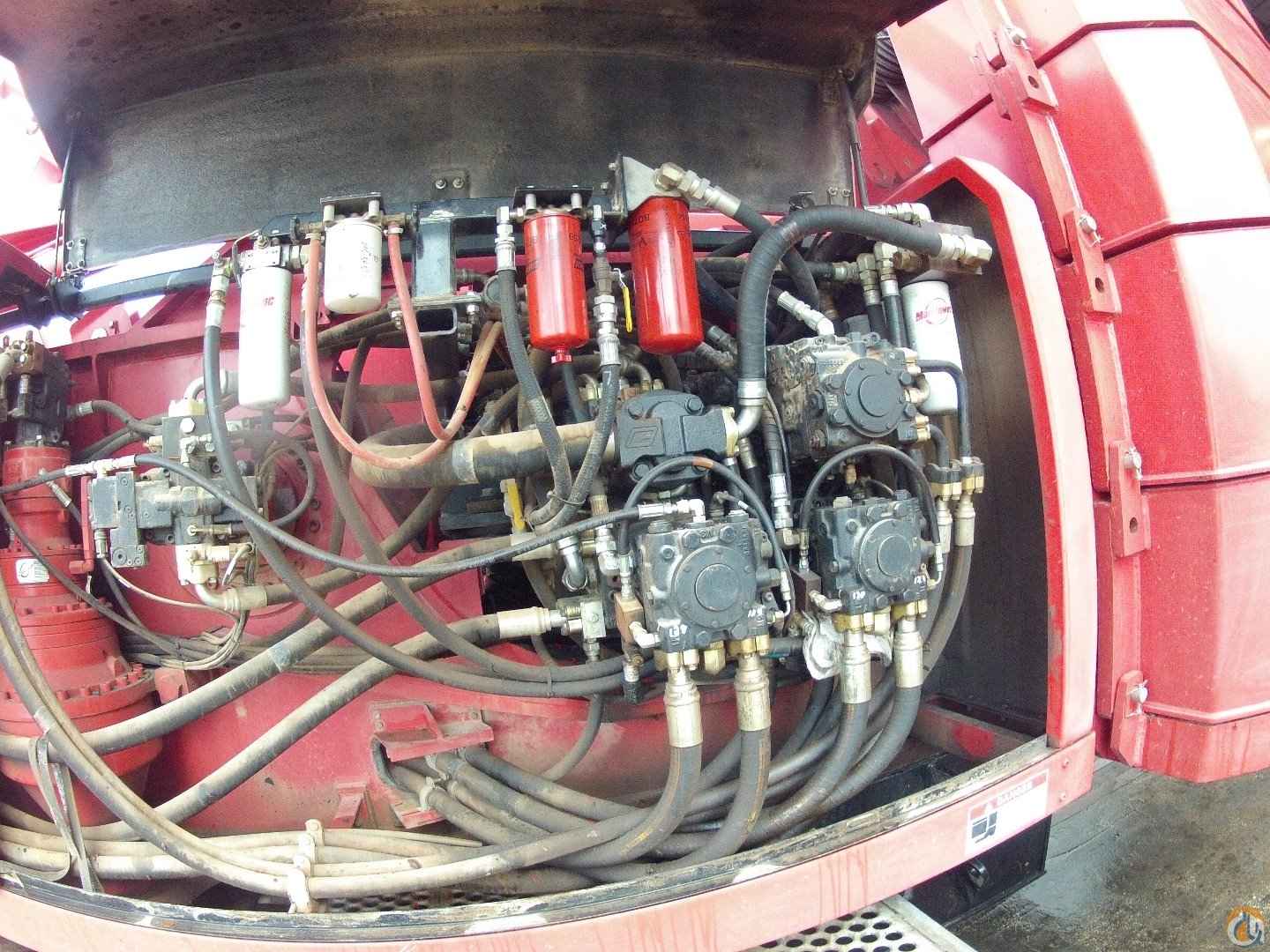

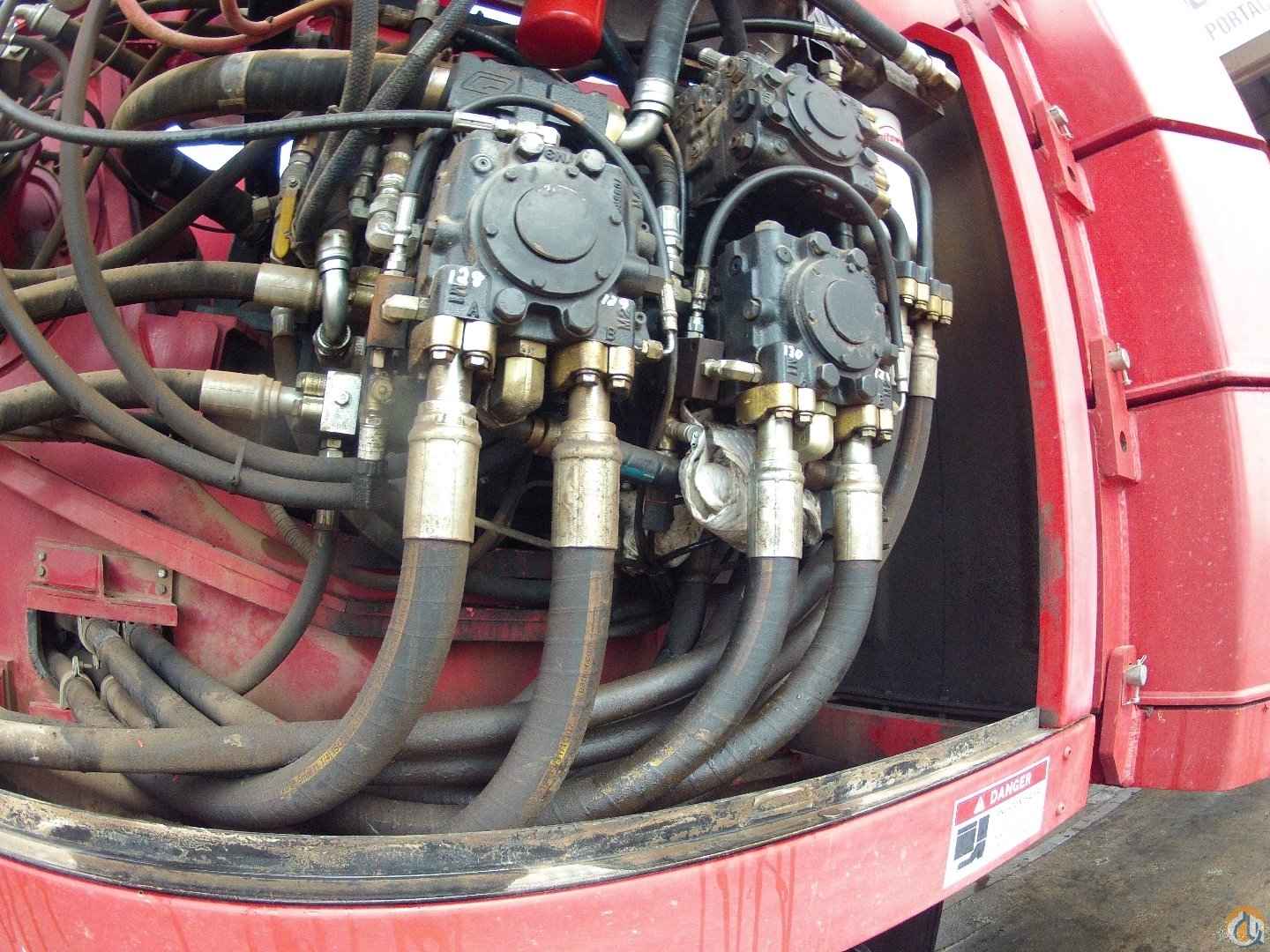

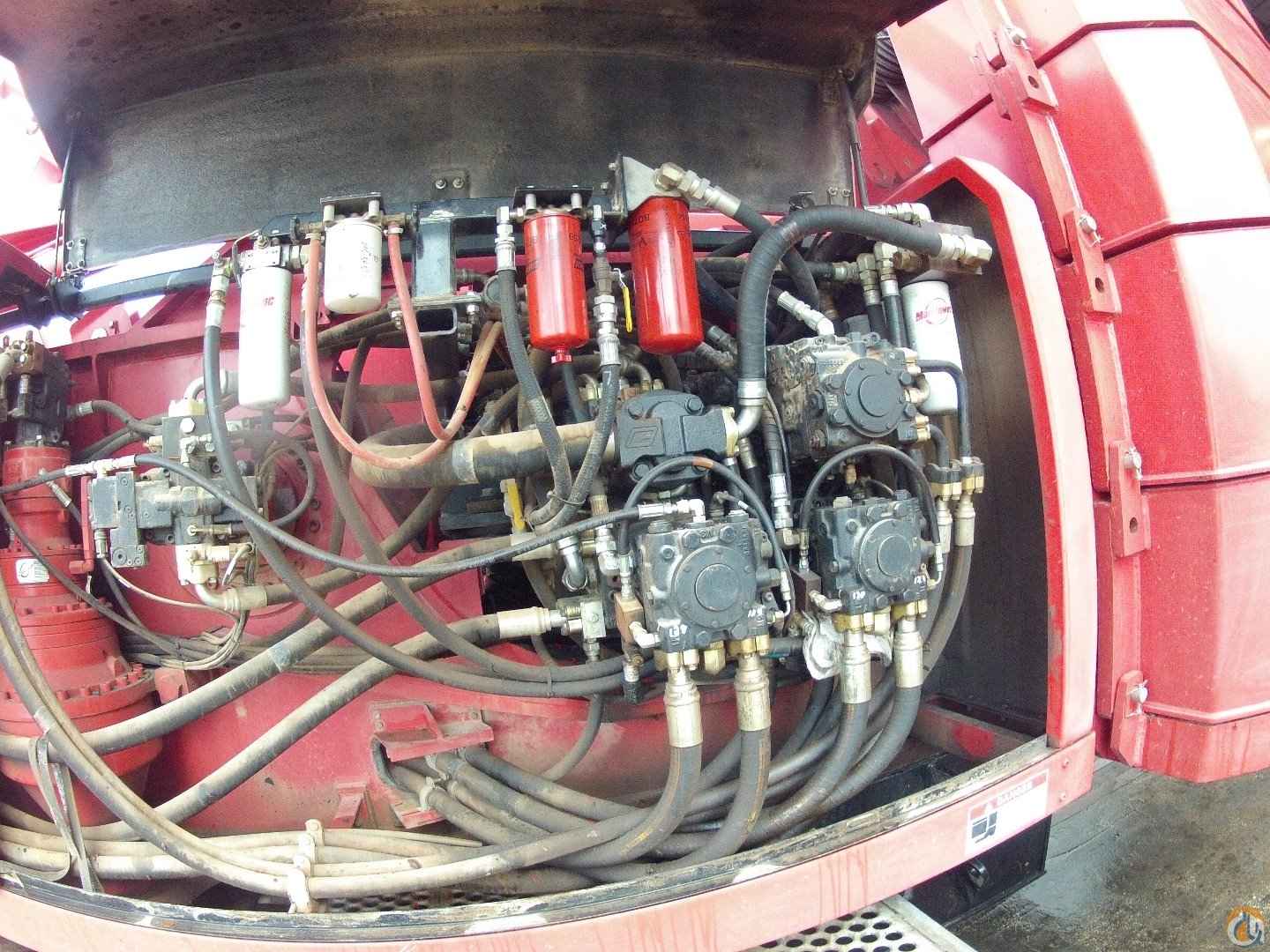

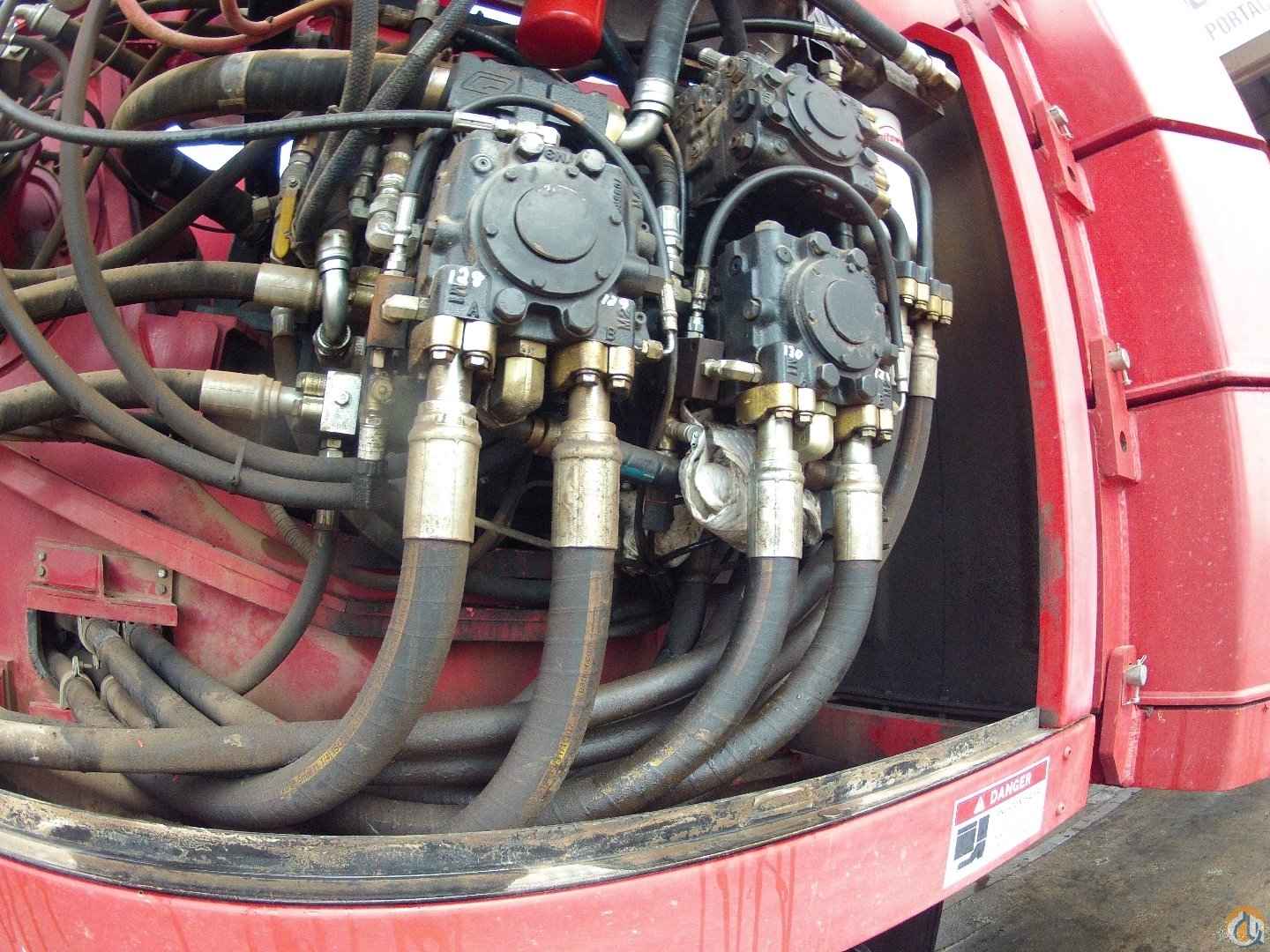

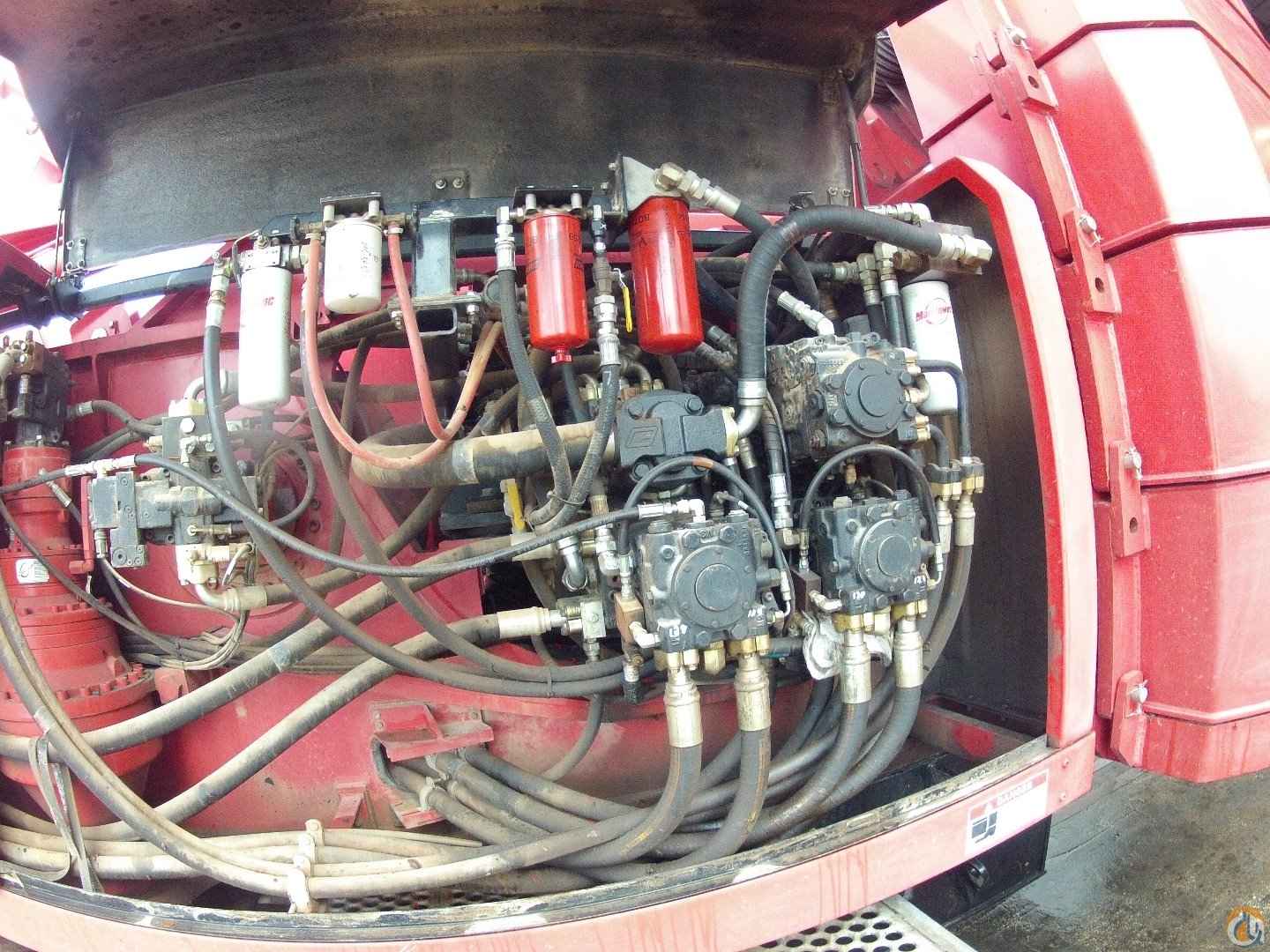

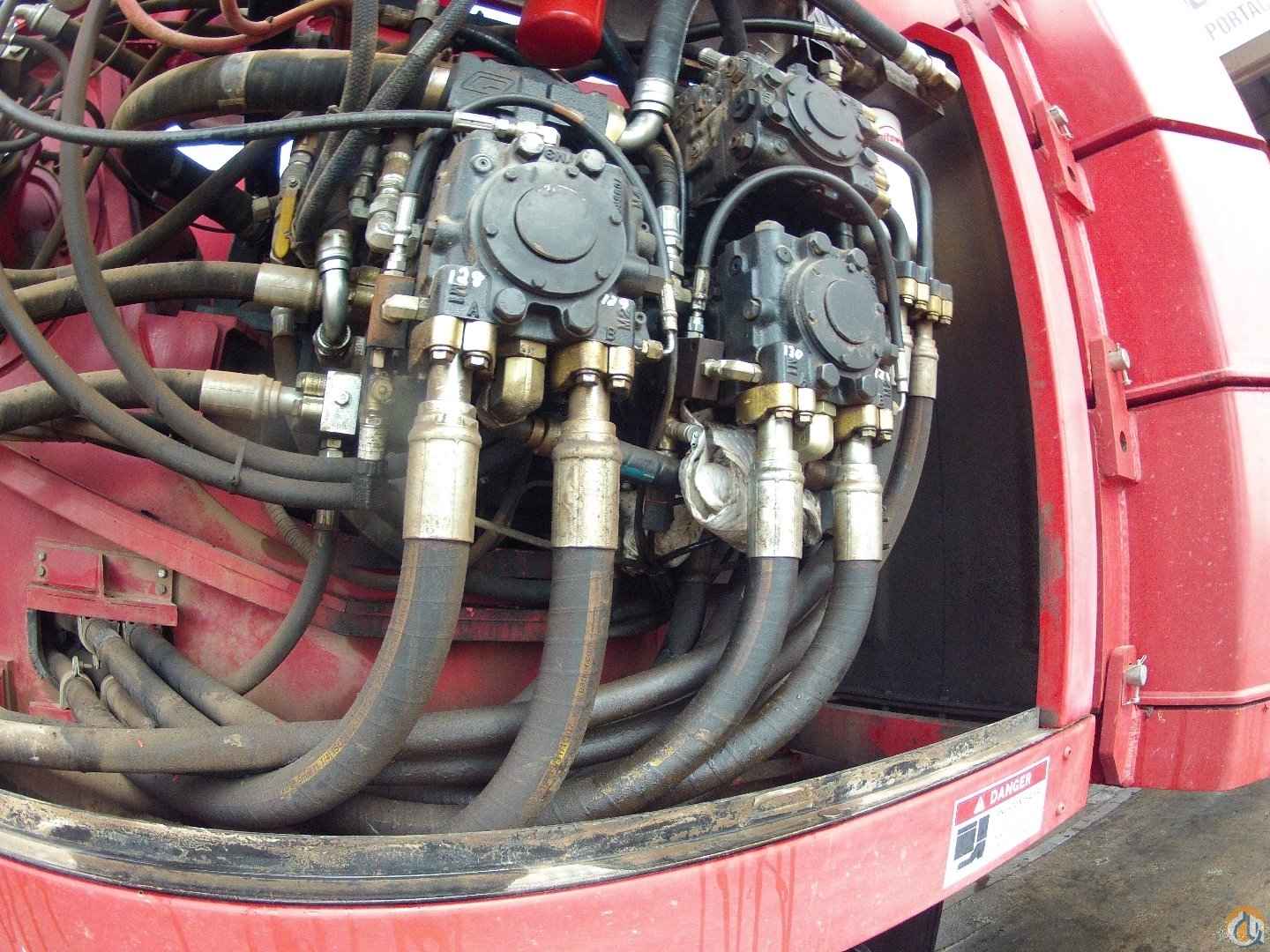

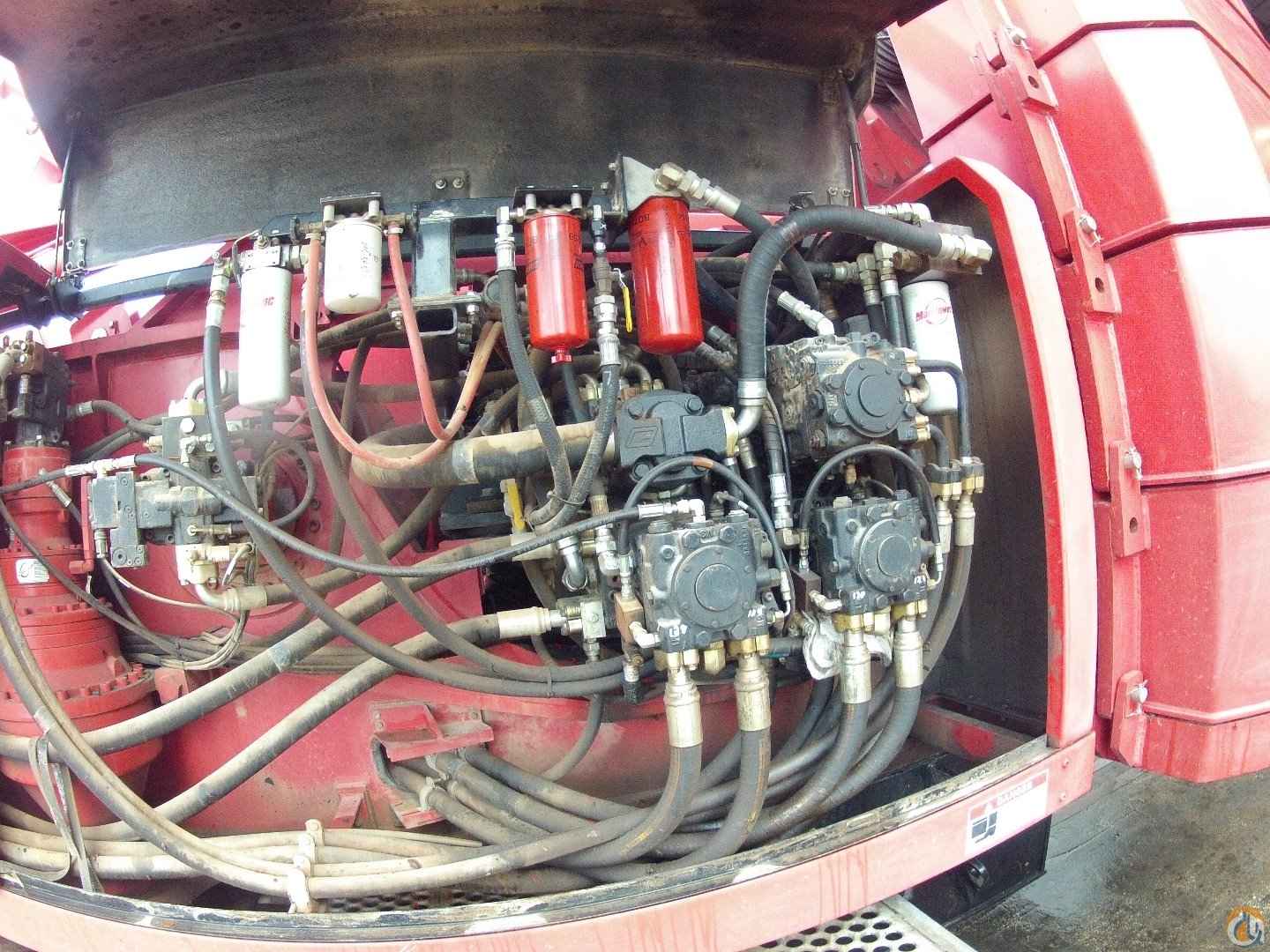

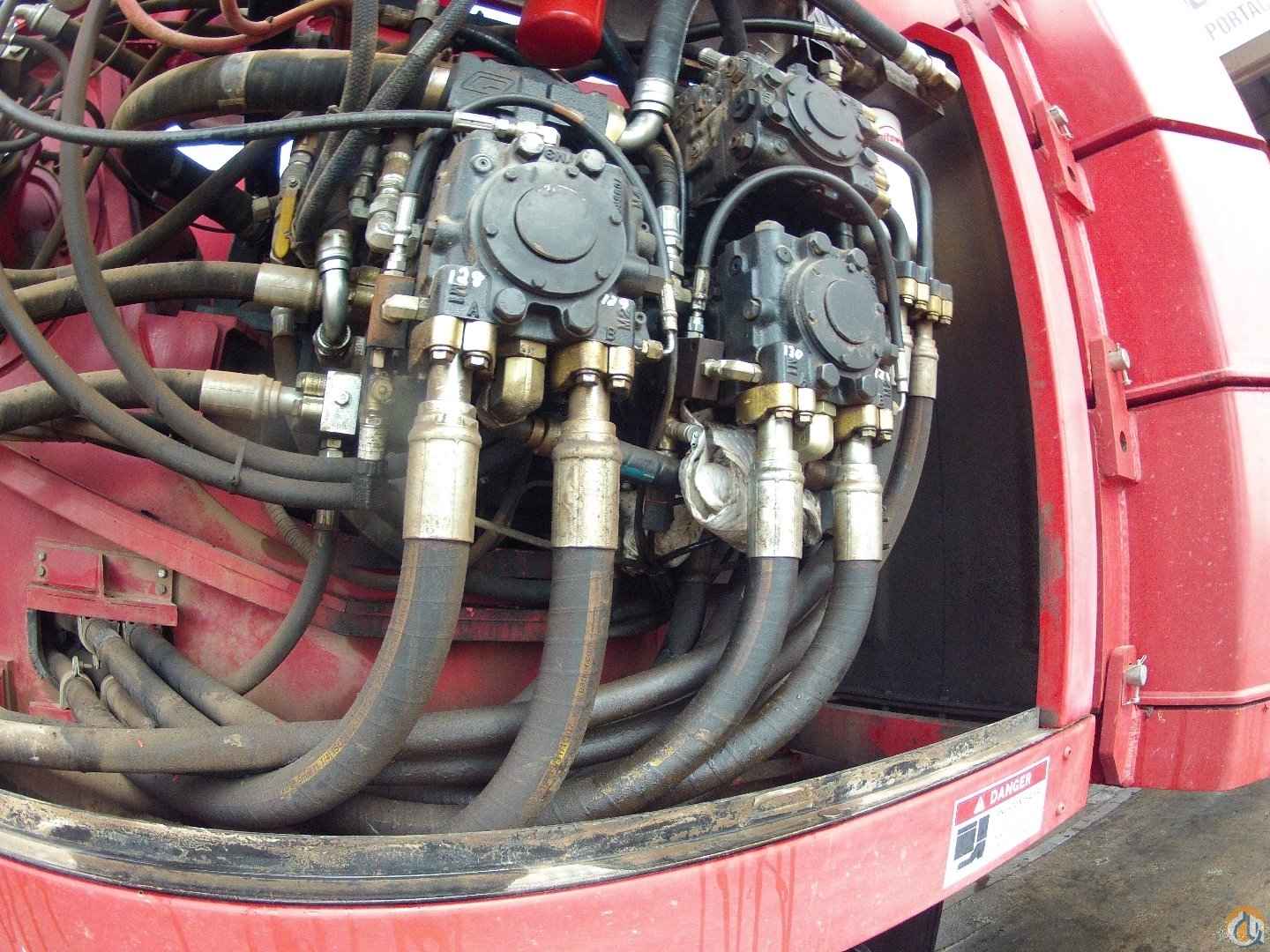

3) Remove all required hydraulic connections and remove upperworks from lowerworks.

4) Remove ROTEC bearing and clean all mounting surfaces.

5) Inspect Rotec mounting surfaces.

6) Install new ROTEC slewing bearing with new bolts and washers, torque as required.

7) Install upper to lower and torque ROTEC as required.

8) Install all removed hoses and hardware with new "O"rings and gaskets.

9) Remove damaged swing planetary unit and inspect mount points.

10) Install new swing planetary assembly utilizing existing motor.

11) Perform full 2000 hr. oil and filter service on upperworks.

- MACHINERY ENCLOSURE (Belle Chasse, LA)-

1) Remove damaged left and right side broken doors from machinery enclosure.

2) Inspect all mounting brackets for enclosure doors for cracks and bends.

3) Install two new enclosure doors on left side of machine covering the drums, pumps, and motors. New doors will be complete with latches and mounting hardware.

4) Remove right enclosure door covering the drum shafts, and repair cracks.

5) Repair right enclosure door, covering hydraulic tank and ladder.

6) Install new hydraulic stabilizers on all repaired doors and align doors.