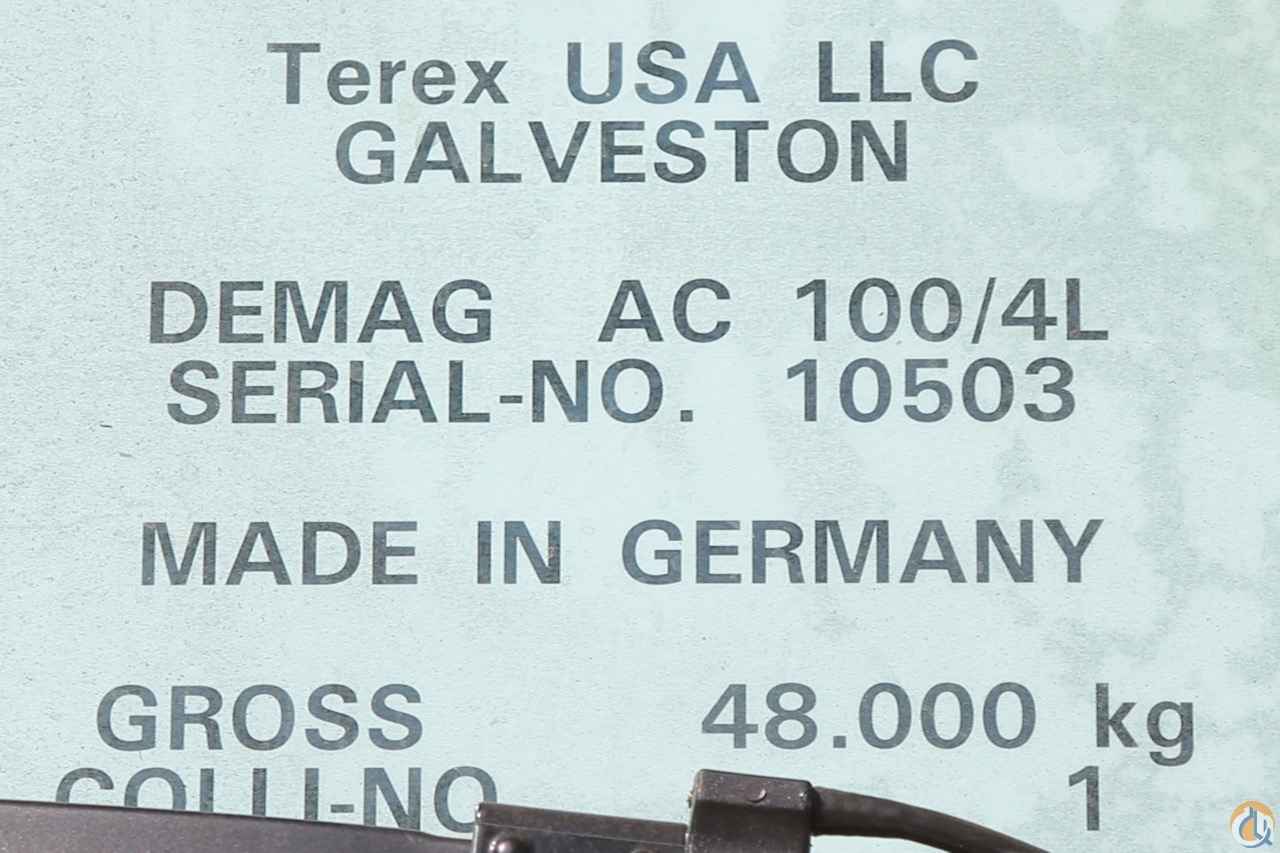

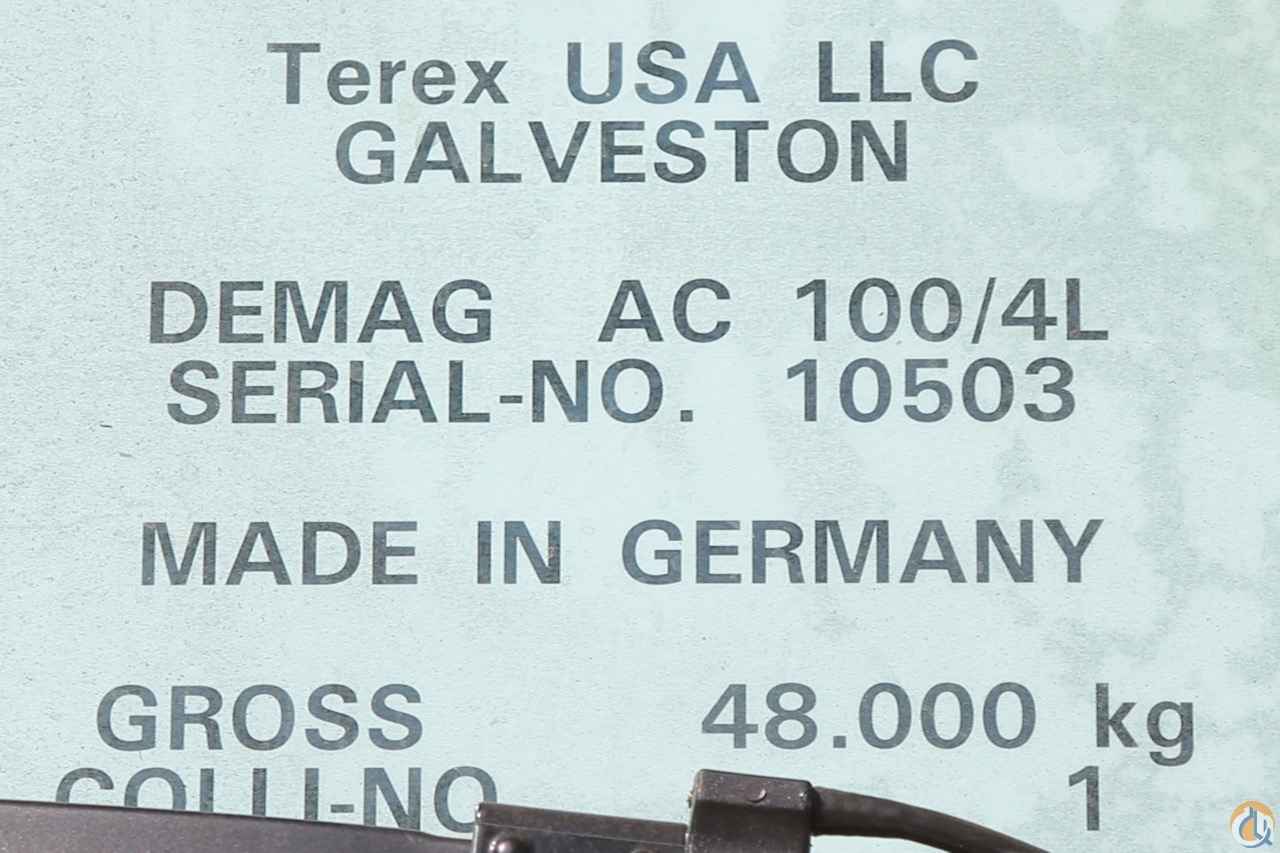

Year: 2017

Capacity: 120.00

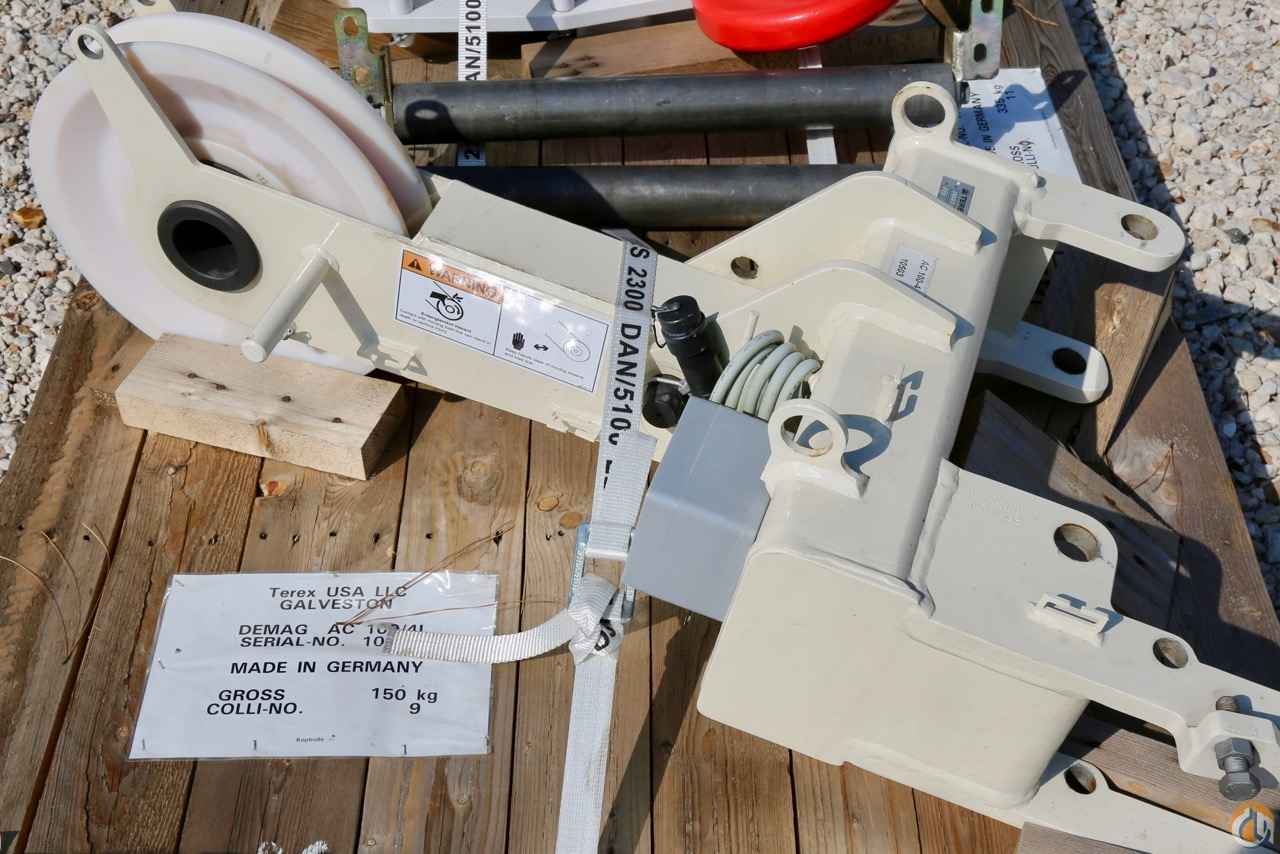

Condition: New

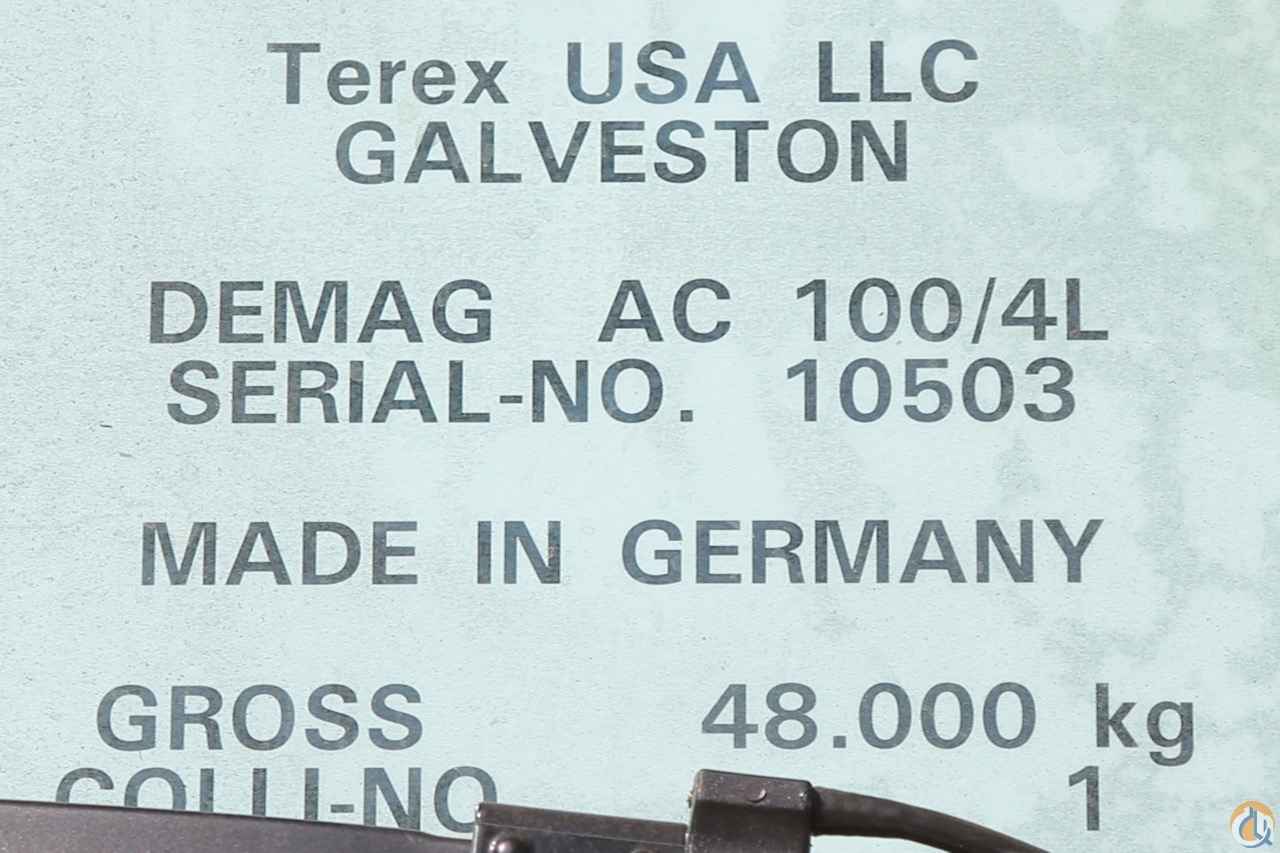

Serial #: 10503

Unit #: BM-2328

Location: Houston, Texas

Boom: 194

Engine – Carrier: EUROMOT 4, TIER 4F MTU 6‐cylinder, water cooled, diesel engine type OM 6R1300; 340kW (462 HP) at 1700 1/min, torque 2200Nm at 1300 1/min; The engine complies with EUROMOT 4, EPA TIER 4 Final; MTU exhaust system made of stainless steel with SCR catalyzer

Fuel tank: 400l Diesel; 40l Ad-Blue

Transmission AS12INT: ZF AS-Tronic; Automated gearbox with integrated hydraulic retarder, 12 forward speeds and 2 reverse; 2-stage transfer case with switchable off-road gear and switchable longitudinal lock

Axles 8x6x8: 8x6x8; 4 axles, axles 1,2,4 driven and equipped with selectable transverse lock; All 4 axles steered

Suspension: Hydropneumatic suspension with axle load compensation; hydraulically lockable; Manual or automatic levelling alternatively

Steering: Dual circuit hydro servocom steering with emergency steering pump; Active rear axle steering (axles 3&4) with 6 different steering programs

Brakes: Pneumatic dual circuit service brake with antilock system, acting on all wheels; Disc brakes; Hydraulic retarder integrated into transmission as wear less, sustained-action brake; Additional exhaust brake and constant throttle valve; spring-loaded parking brake

Wheels: Wheels 385/95R25 (14.00R25); Steel rim 9,5-25/1,7"; Magna MA03 170F; or similar

Wheel Nut Indication: Wheel nut caps with arrow enable optical check of wheel nut position

Cab Carrier 2550: Type 2,55m; Adjustable driver seat with seat heating, armrests and pneumatic suspension; steering wheel height and tilt adjustable; Power door windows; Tinted glass; Aircondition‐ & radio preparation; 2 integrated rotary beacons; Storage area

Co-driver’s seat: Comfort seat for co-driver

Heating Carrier: Engine-dependant warm water heating with 12kW heating power

Radio CD Carrier: Radio with CD-player; For carrier cab

Air-condition carrier: Aircondition for carrier cab with 7KW cooling power

Drive Lights: With low beam, upper beam, daytime running lights , fog lights and cornering lights

Tachograph: Tachograph; Speed indication; Tracking according to country-specific regulations

Cruise Control: Automatic speed control including automatic brake control

Fire Extinguisher: Lose; Mount in carrier cab

Outriggers: H-4-Point design; Vertical and horizontal movement fully hydraulic; Manual or automatic levelling alternatively carrier sideways; 4 outrigger bases

Outrigger pads 028PA: 4 outrigger pads A=0,28m² polyamid, with transport position at vertical cylinder

Outrigger Basis Monitoring: Surveillance of each outrigger beam for visual comparison with the programmed outrigger basis; Displayed in LMI Superstructure cab (Attention: There is no automatic linkage with the LMI‐system)

Stowage Carrier: Storage compartments integrated in topsite of the carrier for lifting accessories partially lockable; Lockable sideways compartments

Electronic immobilizer system: Prevents uncontrolled carrier mobilisation; Incl. 2 electronic keys and 4 ignition keys

Pneumatic tire filling plug: Pneumatic tire filling plug for self-filling of the wheels

Jump Starting device NATO: Jump starting device for carrier and crane according to NATO-standard; Enabling jump start by using 2nd engine or separate energy source

Jumper cable NATO-NATO 10m: 10m long jumper cable with both-sided NATO-plug, adequate for use with any jump starting device with NATO-plugs

Contour safety marking: Continuous, yellow reflecting bands at carrier sides and tail

Emergency roadside kit: Emergency roadside kit for crane operation and for public road access of trucks according to StVZO

Stepladder: Loose stepladder for misc assembly work; Incl. transport storage

Heavy-duty batteries: 4 HD-batteries for optimal battery performance even under HD usage

Illumination: 1x work prefield at superstructure cab, 2x outriggers left, 2x outriggers right

Rotary Beacons: 2x integrated on carrier cab, 2x disconnectable on crane tail

Painting Terex: Duplex basecoat, topcoat in Terex standard, chevron warnings in red-white

Standard Acceptance: Standard acceptance test for superstructure

Telescopic Boom HA60: 12,0m - 59,4m; Single cylinder telescoping system, automatic telescoping; Attachments for all equipment and extensions; 5 sheaves integrated in boom head for max. capacity of 64,6t

Counterweight EG 19T: With EuroMot 4/Tier 4f Engine: Counterweight 19,3t, 5‐pieces (For UK: 4‐pieces); Automatic rigging system; Expandable to max. 24,5t; 4,3t fixed at crane tail

Boom Luffing: Single luffing cylinder with automatic lowering brake valve

Rotary Drive: Single slewing gear unit with spring-loaded multi-disc brake

H1: Hoist with spring-loaded multi-disc brake; Resolver (hoist rotation indicator)

Hook height indication H1: Displaying and programmability of the hook height H1 by IC-1

Engine 129-3a, TIER 3: MTU diesel engine type OM 904 LA; 129kW (175HP) at 2200 1/min, torque 675Nm at 1200 1/min; The engine complies with EUROMOT 3a, EPA TIER 3 and Carb regulations; Exhaust system cpl. stainless steel, incl. spark arrester

Drive: Hydraulic system with power control; Hydraulic oil cooler

Control System: Enabling 4 simultaneous working movements; electric pilot controls via 2 two-axis joysticks

Operator aids: IC-1, with integrated load moment indicator acc. EN13000; Colour display; Displaying of current operating conditions, load charts, fault indicator; Signal lights indicating LMI-load; Crane data logger; deadman switch in joysticks and seat crane cab

Working range limiter: Displaying and programmability of the work range limits by IC-1

Cab superstructure 0875: Type 0,875m; Tilt variable 20°; Seat heating; Fold-out front window; Extendable side & foldable front pedestal; Handrails; Tinted safety glass; pull-down sun visor and light curtains; Aircondition- & radio preparation

Radio CD Superstructure: Radio with CD-player; For Superstructure cab

Heating Superstructure: Engine-dependant warm water heating with 12kW heating power

Engine-independent heating superstructure: Auxiliary, engine independent warm water heating with 5kW heating power; With timer; Switchable between engine block and superstructure cab

Air-condition superstructure: Aircondition in crane cab with 7KW cooling power

Anemometer: Disconnectable, to allow use with all extensions

Illumination: 1x work light for prefield at superstructure cab

Rotary Beacons: 2x Disconnectable on crane tail

Preparation for R1 (Swing away rooster sheave): For later swing away rooster sheave retrofitting

Painting DEMAG: Single basecoat, topcoat in DEMAG standard, chevron warnings in red-white

Standard Acceptance: Standard acceptance test for superstructure

Basic machine: AC100/4(L) INCLUDING ABOVE.

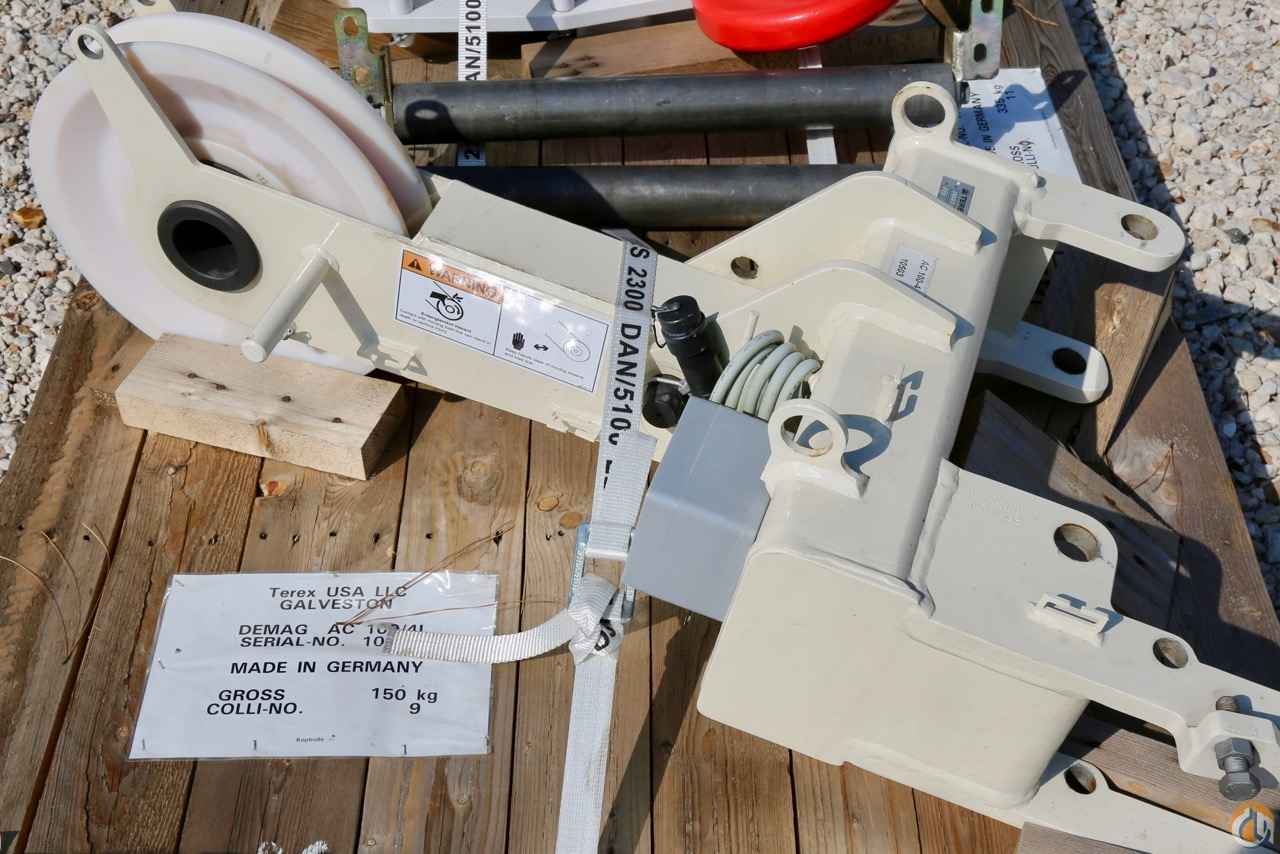

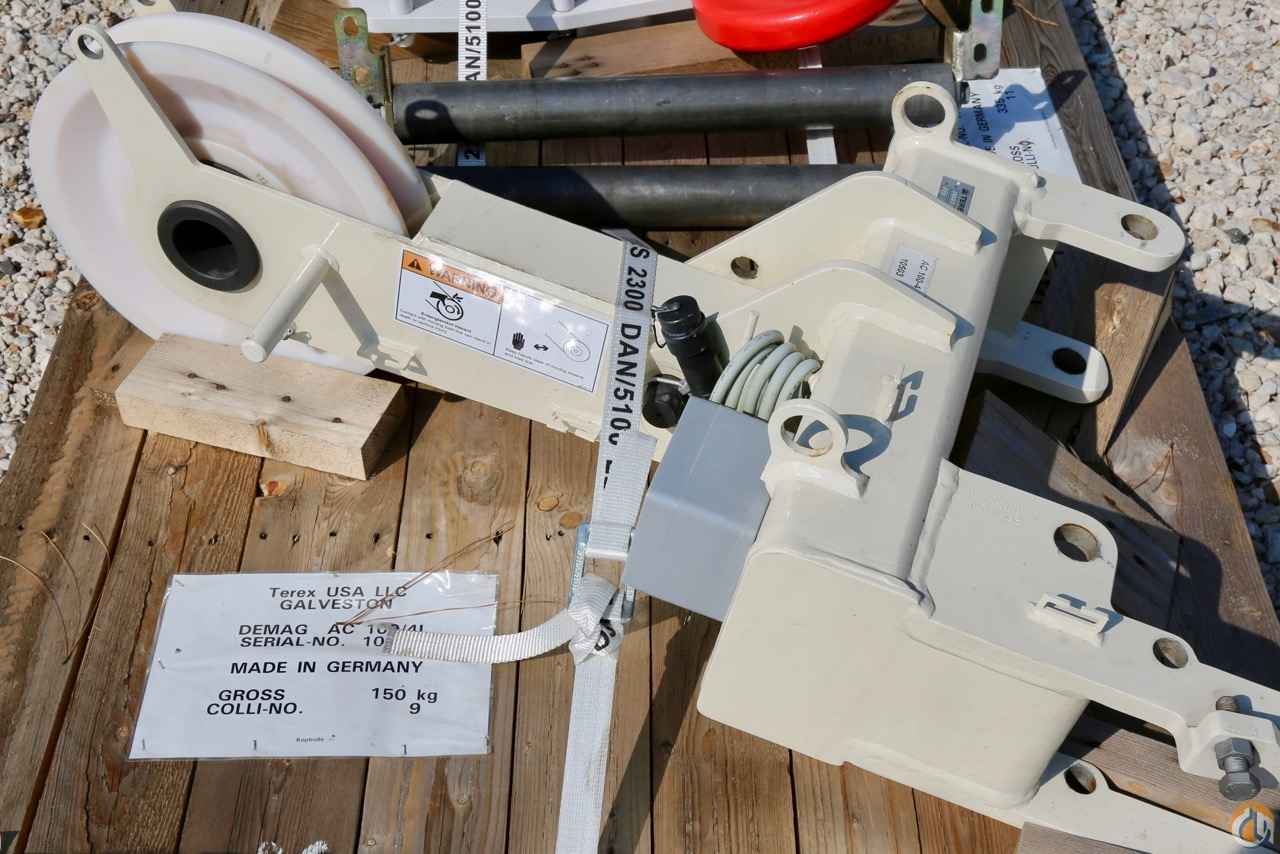

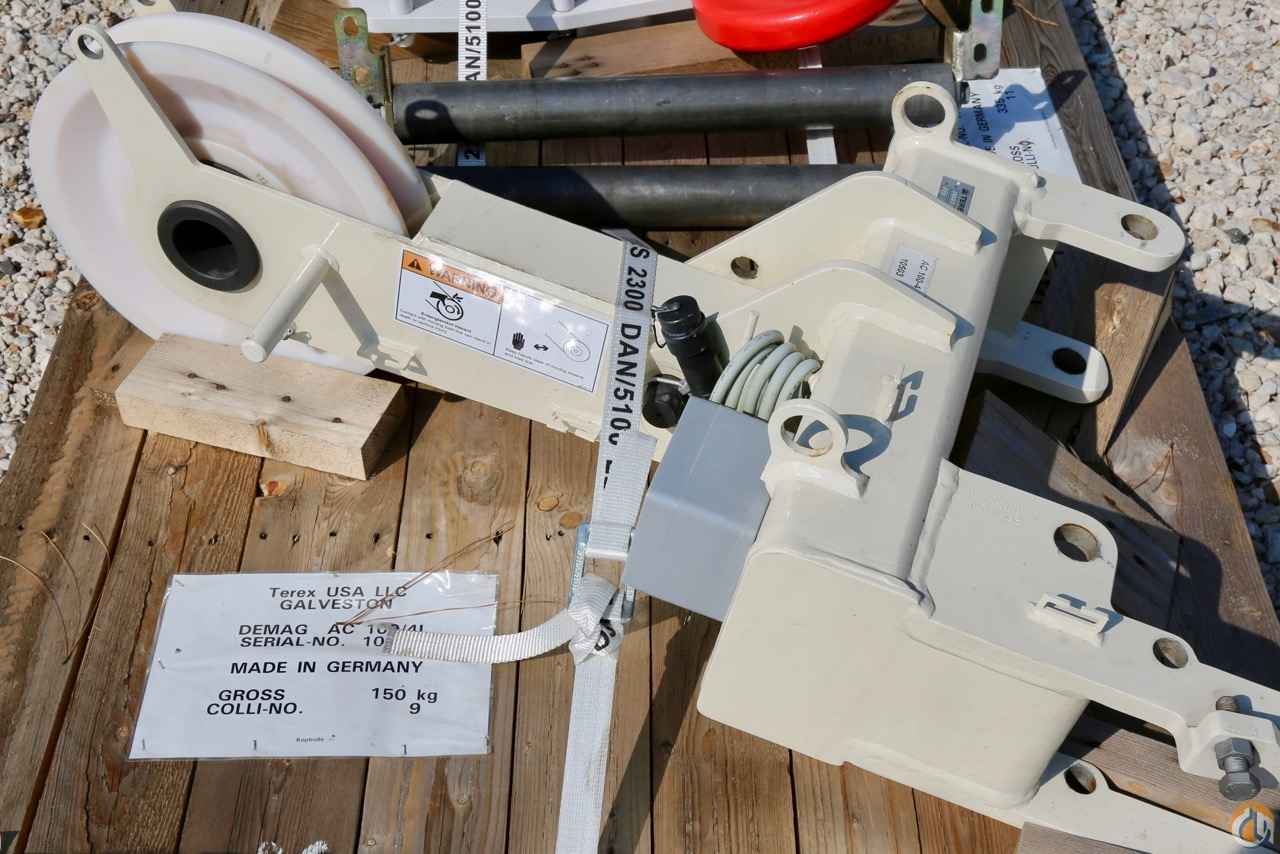

HAV-HY 27m: 27m; Variable extension with double folding swing-away jib, hydraulic, stepless offset 0°-40°; 1-sheave head; Incl. transport storage; Includes HAV-HY 19m

R1 (Swing away rooster sheave): Swing-away rooster sheave, incl. transport storage; For single-reeving operation with elevated hook height"

Hook block 80-5-18-D: 80-5-18-D (650kg); Hook block with ramshorn hook; white with red signal stripes

Hook block 50-3-18-E: 50-3-18-E (550kg); Hook block with single hook; white with red signal stripes

Hook block 20-1-18-E: 20-1-18-E (350kg); Hook block with single hook; white with red signal stripes

Hook 8-0V-E-170: 8-0V-E (170kg); single hook with vertical swivel; red

S1 Heavy lift attachment stage 1: 2 additional sheaves; Dis-connectable; For total 7 sheaves at boom head; Max. capacity of 80t

EUROMOT 4, TIER 4F (Instead of std. engine 3a):

• For carrier:MTU 6-cylinder, water cooled, diesel engine type OM 6R1300; 340kW (462HP) at 1700 1/min, torque 2200Nm at 1300 1/min; The engine complies with EUROMOT 4, EPA TIER 4final; MTU exhaust system made of stainless steel with SCR catalyserFuel tank: 400l Diesel; 40l Ad-Blue.

• For superstructure:MTU 4-cylinder,water cooled, diesel engine type 4R1000; 129kW (175HP) at 2200 1/min, torque 750Nm at 1600 1/min; The engine complies with EUROMOT 4, EPA TIER 4F and Carb regulations; MTU exhaust system made of stainless steel with SCR catalyserFuel tank: 200l Diesel; 20l Ad-Blue"

Rear view camera: Monitor in carrier cab

Central lubrication carrier: Central auto lube for all lubrication points at carrier

Remote control: Control of rigging and superstructure operations via wireless remote control

H2X: H2 hoist; Spring-loaded multi-disc brake; Resolver (hoist rotation indicator); Incl. quick couplings and transport frame; Self-rigging

IC‐1 Plus (Asymmetric Outrigger Positioning): Asymmetrical outrigger positioning makes it possible to work with asymmetrically extended outriggers; Note: Counterweight detection and Outrigger load indicator are included. To be added to stock crane by Terex during or around the time of in-service.

Xenon work floodlight 1: Out of superstructure cab adjustable xenon floodlight, at front support boom base section

Positioning light: Disconnectable red beacon, to allow use with all extensions

Central lubrication superstructure: Central auto lube for all lubrication points at Superstructure

Additional counterweight 5,2t: For EuroMot 4/Tier 4f (For EG/NEG/UK): Additional counterweight 5,2t, two pieces; For max. 24,5t counterweight with 7-pieces (For UK 6-pieces)

Toolkit: Toolkit for light repairs and service

Wheels 445/95 (16.00R25) Bridgestone VHS2 174F: Wheels 445/95R25 (16.00R25); Steel rim 11-25/1,7"; Bridgestone VHS2 174F instead of TechKing ETGC 170F or similar 385/95 (14.00R25)

Display screen: Display screen for the different cameras enable for monitoring in superstructure cabin

Hoist monitoring H1: Visualisation H1 by a camera system; Displayed on additional screen for the hoist monitoring in superstructure cabin

Hoist monitoring H2: Visualisation H2 by a 2nd camera system; Displayed on additional screen for the hoist monitoring in superstructure cabin

Side mirror: Mirror enabling visual observation of the superstructure cab's opposite side

Additional work lights on superstructure cab: Additional work lights on top of the superstructure cabin; Manually adjustable

Battery disconnecting switch: Battery disconnecting switch for disconnection of the voltage source and the on-board power supply in carrier and superstructure

Dolly preparation 4-point variable (4PV): 4-point support brackets enable individual positioning of a dolly; Incl. freewheel for slewing gear unit and luffing cylinder, quick couplings for brake air & electrics; Dolly and dolly adapter are not included

Omit CE & EN13000: Built according to CE, but without CE documentation and without declaration of conformity; Deactivation of the specific EN13000 overload protection software

Rope H1 US JP: Alternative rope 2160 for H1; US-specific; Japan

Rope H2 US JP: Alternative rope 2160 for H2; US-specific; Japan

Painting TEREX (Instead of DEMAG): Single basecoat, topcoat in TEREX standard instead of DEMAG standard, chevron warnings in red-white

DOT / OSHA / PDI & Inservice at our Yard in Houston, TX

Sold Exworks Houston, TX

Sales Dept: 1-866-458-5915

Fax: 713-491-9359

7795 Little York Road, Houston, TX 77016, United States