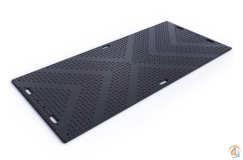

Outrigger Pads 24"x24"x1.5"

Kerry Koberg: 866-717-6097

Last Updated: 20 Jul 2021

Condition: New

SPECIFICATIONS

- Model: PSC-SL-2424-1.5-Y

- Interlocking Sytem: Slot Lock Flange

- WxLxH: 24"x24"x1.5"

- Approximate Area: 4 sq. ft.

- Weight: 29 LBS

- Crush Rating: 500 PSI

- Working Load Limit: 100,000 LBS

- Color: Hi-Viz Yellow

OVERVIEW

- The PSC-SL-D2424-1.5-Y Hi-Viz Yellow DICA SafetyTech® Outrigger Pad is a base pad for ProStack SlotLock Flange Cribbing Blocks.

- The recessed slots on the SafetyTech Pad receive the end flanges of ProStack Slot Lock Cribbing Blocks to create a solid interlocking cribbing setup.

CRIBBING BLOCK KIT

- Items sold separately, suggested quantities below are per outrigger foot.

- Base Pad Options:

- (1) PSC-SL-D2424-1.5 SafetyTech (BLACK) Outrigger Pad

- (1) PSC-SL-D2424-1.5-Y SafetyTech (HI-VIZ YELLOW) Outrigger Pad.

- Cribbing Blocks:

- (4) PSC-SL-100 ProStack SLOT LOCK Interlocking Cribbing Blocks

- Grip Pad:

CRIBBING BLOCK GENERAL GUIDELINES & FAQ'S

Stacking

- ProStack Cribbing is designed to be stacked.

- The height to which the cribbing can be stacked is subject to the cribbing being used and the situation.

- Medium duty 12"x12"x6" ProStack cribbing blocks in ideal conditions should not be stacked higher than 3' without evaluation by trained and experienced personnel under the direction of a qualified technician or engineer trained in cribbing applications and safety.

- ProStack cribbing is designed to create a solid stack (without gaps). This type of set-up maximizes surface area contact, stability and support.

- The Army Core of Engineers recommends limiting (wood box crib) configurations to three times width (Shortest width for Non-Square Cribs).

- Box cribs: The standard is a 4x4 box crib with four contact points. Other configurations are shown in the Army Corps of Engineers diagrams.

- Height is always subject to the situation.

Guidelines

- Be certain that the ground, floor, or other surface is capable of supporting the combined weight of the crib structure and the load to be supported. Never build cribbing on loose or unstable ground.

- Never exceed the maximum capacity of the cribbing.

- A-Frame Outriggers/Stabilizers: Take special precautions when deploying A-frame outriggers onto any cribbing set-up. Lateral forces need to be accounted for to avoid potential toppling of the set-up.

- ProStack cribbing should be constructed by trained and experienced personnel under the direction of a qualified technician or engineer trained in cribbing applications and safety.

- Do not use cribbing if it is cracked, split, warped, or damaged.

- Never use chemically damaged cribbing.

- Do not allow personnel to climb or hang onto cribbing.

- Whenever possible, avoid intermixing wood, metal, or other forms of cribbing with plastic cribbing.

- Ideal Conditions:

- The surface is flat and Level and fully capable of supporting the load and pressures.

- The load exerted onto the cribbing set-up is vertical.

Can ProStack Pyramid Interlocking Cribbing Blocks be used without using a DICA PSC SafetyTech Base Pad?

- Yes, ProStack Cribbing Blocks can be used without a DICA PSC SafetyTech Base Pad.

- Refer to the General Guidelines.

- Refer to the DICA ProStack Cribbing Situational Height Considerations.

- The purpose of the DICA PSC SafetyTech Base Pads is to:

- Allow for full contact between the cribbing blocks and the base pad to reduce contact pressure.

- Allow for a fully interlocked solution, and eliminate any opportunity for lateral movement at the contact point between the cribbing blocks and the supporting surface

- Prevent damage to the pyramids due to highly concentrated pressure.

- The height of the stack created should be evaluated by trained and experienced personnel under the direction of a qualified technician or engineer trained in cribbing application safety.

- Use of a Neoprene pad or other soft squish-able material that will not crush under high pressure is recommended to prevent damage to the interlocking pyramids and increase friction between the cribbing blocks and the surface they are placed on.

Can ProStack Cribbing Blocks be used without a neoprene pad being placed between the load contact point and the top cribbing block or block?

- Yes, ProStack Cribbing Blocks can be used without a Neoprene Friction Pad placed between the load contact point and the cribbing blocks.

- The purpose of the Neoprene Friction Pad being placed between the load contact point and the cribbing blocks is to:

- Increase friction between the two points and further minimize the chances of lateral movement.

- Prevent damage to the pyramids due to highly concentrated pressure.

- If a neoprene pad is not available, look to use other soft, squish-able materials that will not crush under high pressures. Plywood of an adequate condition and thickness could be an option in this case.

- Cribbing set-ups should be evaluated by trained and experienced personnel under the direction of a qualified technician or engineer trained in cribbing application safety.

Make Your Setup Safe®

DICA Outrigger Pads

dicausa.comContact: Kerry Koberg, Director, Sales & Strategic Accounts

Phone: 866-717-6097

Condition

New

0 views this week

0 people have saved

Condition

New

SPECIFICATIONS

- Model: PSC-SL-2424-1.5-Y

- Interlocking Sytem: Slot Lock Flange

- WxLxH: 24"x24"x1.5"

- Approximate Area: 4 sq. ft.

- Weight: 29 LBS

- Crush Rating: 500 PSI

- Working Load Limit: 100,000 LBS

- Color: Hi-Viz Yellow

OVERVIEW

- The PSC-SL-D2424-1.5-Y Hi-Viz Yellow DICA SafetyTech® Outrigger Pad is a base pad for ProStack SlotLock Flange Cribbing Blocks.

- The recessed slots on the SafetyTech Pad receive the end flanges of ProStack Slot Lock Cribbing Blocks to create a solid interlocking cribbing setup.

CRIBBING BLOCK KIT

- Items sold separately, suggested quantities below are per outrigger foot.

- Base Pad Options:

- (1) PSC-SL-D2424-1.5 SafetyTech (BLACK) Outrigger Pad

- (1) PSC-SL-D2424-1.5-Y SafetyTech (HI-VIZ YELLOW) Outrigger Pad.

- Cribbing Blocks:

- (4) PSC-SL-100 ProStack SLOT LOCK Interlocking Cribbing Blocks

- Grip Pad:

CRIBBING BLOCK GENERAL GUIDELINES & FAQ'S

Stacking

- ProStack Cribbing is designed to be stacked.

- The height to which the cribbing can be stacked is subject to the cribbing being used and the situation.

- Medium duty 12"x12"x6" ProStack cribbing blocks in ideal conditions should not be stacked higher than 3' without evaluation by trained and experienced personnel under the direction of a qualified technician or engineer trained in cribbing applications and safety.

- ProStack cribbing is designed to create a solid stack (without gaps). This type of set-up maximizes surface area contact, stability and support.

- The Army Core of Engineers recommends limiting (wood box crib) configurations to three times width (Shortest width for Non-Square Cribs).

- Box cribs: The standard is a 4x4 box crib with four contact points. Other configurations are shown in the Army Corps of Engineers diagrams.

- Height is always subject to the situation.

Guidelines

- Be certain that the ground, floor, or other surface is capable of supporting the combined weight of the crib structure and the load to be supported. Never build cribbing on loose or unstable ground.

- Never exceed the maximum capacity of the cribbing.

- A-Frame Outriggers/Stabilizers: Take special precautions when deploying A-frame outriggers onto any cribbing set-up. Lateral forces need to be accounted for to avoid potential toppling of the set-up.

- ProStack cribbing should be constructed by trained and experienced personnel under the direction of a qualified technician or engineer trained in cribbing applications and safety.

- Do not use cribbing if it is cracked, split, warped, or damaged.

- Never use chemically damaged cribbing.

- Do not allow personnel to climb or hang onto cribbing.

- Whenever possible, avoid intermixing wood, metal, or other forms of cribbing with plastic cribbing.

- Ideal Conditions:

- The surface is flat and Level and fully capable of supporting the load and pressures.

- The load exerted onto the cribbing set-up is vertical.

Can ProStack Pyramid Interlocking Cribbing Blocks be used without using a DICA PSC SafetyTech Base Pad?

- Yes, ProStack Cribbing Blocks can be used without a DICA PSC SafetyTech Base Pad.

- Refer to the General Guidelines.

- Refer to the DICA ProStack Cribbing Situational Height Considerations.

- The purpose of the DICA PSC SafetyTech Base Pads is to:

- Allow for full contact between the cribbing blocks and the base pad to reduce contact pressure.

- Allow for a fully interlocked solution, and eliminate any opportunity for lateral movement at the contact point between the cribbing blocks and the supporting surface

- Prevent damage to the pyramids due to highly concentrated pressure.

- The height of the stack created should be evaluated by trained and experienced personnel under the direction of a qualified technician or engineer trained in cribbing application safety.

- Use of a Neoprene pad or other soft squish-able material that will not crush under high pressure is recommended to prevent damage to the interlocking pyramids and increase friction between the cribbing blocks and the surface they are placed on.

Can ProStack Cribbing Blocks be used without a neoprene pad being placed between the load contact point and the top cribbing block or block?

- Yes, ProStack Cribbing Blocks can be used without a Neoprene Friction Pad placed between the load contact point and the cribbing blocks.

- The purpose of the Neoprene Friction Pad being placed between the load contact point and the cribbing blocks is to:

- Increase friction between the two points and further minimize the chances of lateral movement.

- Prevent damage to the pyramids due to highly concentrated pressure.

- If a neoprene pad is not available, look to use other soft, squish-able materials that will not crush under high pressures. Plywood of an adequate condition and thickness could be an option in this case.

- Cribbing set-ups should be evaluated by trained and experienced personnel under the direction of a qualified technician or engineer trained in cribbing application safety.

Make Your Setup Safe®

Rental Prices

Please contact the dealer for pricing -- 866-717-6097

Email Seller

Advertisements